Miya Bholat

Miya Bholat

Oct 08, 2025

How CMMS Software Can Transform Fleet Management

How CMMS Software Transforms Your Fleet Operations

Managing a fleet of vehicles without the right tools feels like trying to juggle flaming torches while blindfolded. You're constantly putting out fires instead of preventing them. That's where CMMS fleet maintenance software steps in to save the day—and your sanity.

If you're running trucks, delivery vans, construction equipment, or any fleet of vehicles, you already know that unexpected breakdowns don't just cost money. They derail schedules, frustrate customers, and keep you awake at night wondering what will break next.

What Exactly Is CMMS for Fleet Maintenance?

CMMS stands for Computerized Maintenance Management System, and is synonymous with Fleet Maintenance Software.

This fleet software tracks every detail about your fleet's maintenance needs, from oil changes to major overhauls. It schedules preventive maintenance, manages work orders, tracks parts inventory, and gives you the data you need to make smart decisions about your vehicles.

The Real-World Benefits of CMMS for Fleets

Stop Playing Maintenance Roulette

Without CMMS software, you're essentially gambling with your fleet's health. You might remember that truck #47 needs an oil change "sometime soon," but what about the transmission service on van #23? Or the brake inspection that's overdue on vehicle #8?

CMMS software eliminates this guesswork. It automatically schedules maintenance based on mileage, engine hours, or calendar dates. Your vehicles get the care they need before problems become expensive disasters.

Cut Costs Without Cutting Corners

Here's something that might surprise you: preventive maintenance actually saves money. A lot of money. When you catch issues early, you're looking at a $200 repair instead of a $2,000 replacement. CMMS software helps you spot these opportunities consistently.

The software also optimizes your parts inventory. Instead of overstocking expensive parts "just in case" or running out when you desperately need them, you maintain the right balance. This alone can free up thousands of dollars in working capital.

Boost Your Fleet's Uptime

Every minute a vehicle sits in the shop costs you money. CMMS software minimizes downtime by scheduling maintenance during slow periods and ensuring technicians have everything they need before starting work.

When maintenance is predictable, your operations become predictable too. You can schedule jobs confidently, knowing your vehicles will be available when needed.

Key Fleet Features That Make the Difference

Automated Scheduling That Actually Works

The best CMMS fleet maintenance software doesn't just remind you about upcoming maintenance—it intelligently schedules it. The system considers your vehicle usage patterns, seasonal demands, and technician availability to suggest optimal maintenance windows.

Real-Time Vehicle Health Monitoring

Modern CMMS platforms integrate with GPS and telematics devices to monitor your vehicles in real-time. Engine fault codes, fuel efficiency drops, and other warning signs trigger automatic alerts. You know about problems before they strand your drivers on the highway.

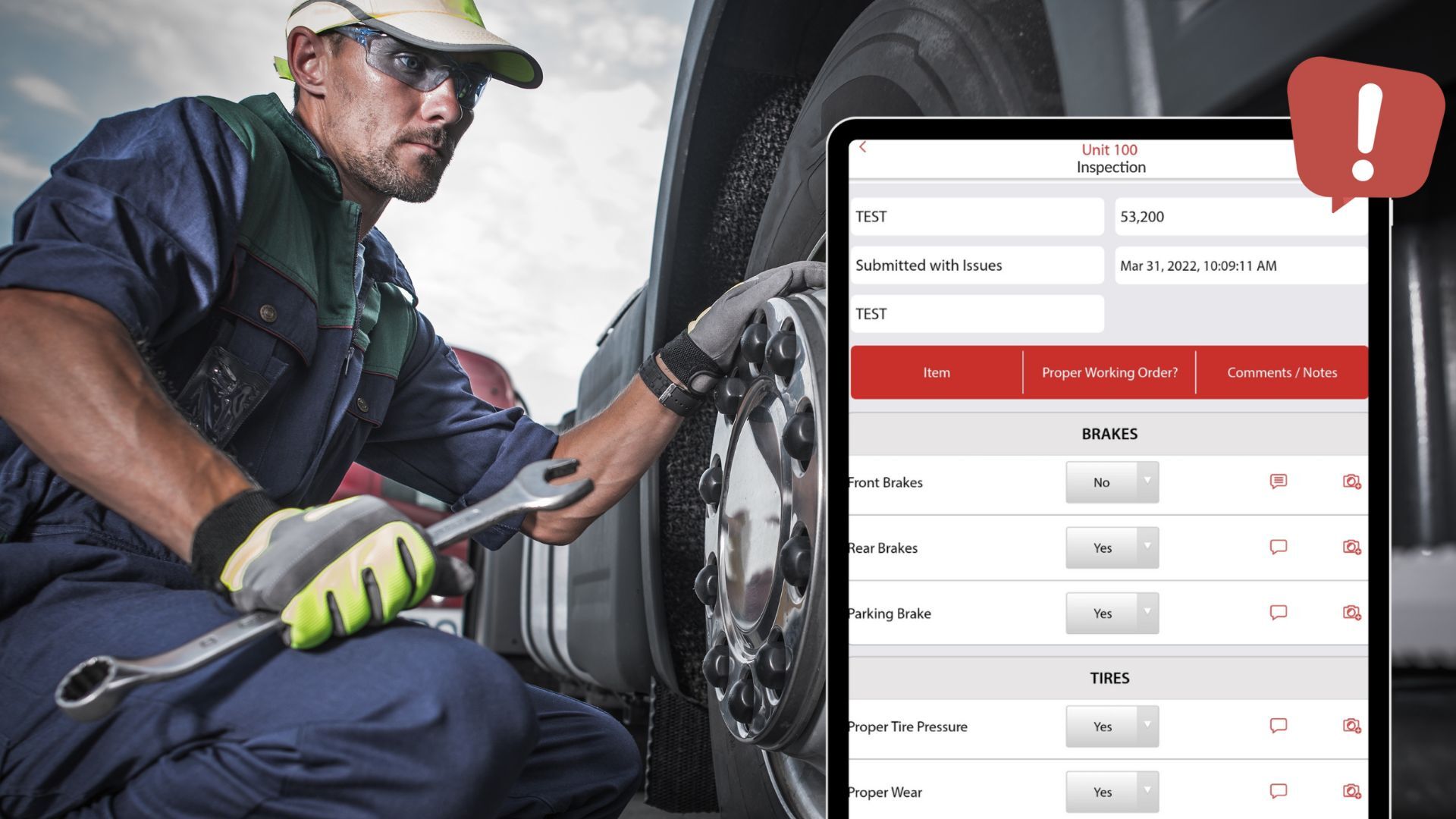

Mobile Access for Field Teams

Your technicians and drivers don't work from desks, so why should your maintenance software? Mobile-friendly CMMS platforms let field teams update work orders, report issues, and access vehicle histories from anywhere.

Comprehensive Reporting and Analytics

Numbers tell stories, and CMMS software helps you read them. Which vehicles cost the most to maintain? Are certain routes harder on your fleet? What's your average repair cost per mile? This data guides smarter fleet management decisions.

How CMMS Software Transforms Daily Operations

For Fleet Managers

Instead of juggling spreadsheets and sticky notes, fleet managers get a clear dashboard showing exactly what needs attention. They can spot trends, allocate resources efficiently, and prove ROI to leadership with concrete data.

For Technicians

Mechanics receive detailed work orders with complete vehicle histories, parts lists, and step-by-step procedures. No more hunting for information or discovering missing parts halfway through a job.

For Drivers

Drivers can quickly report issues through mobile apps, complete pre-trip inspections digitally, and get real-time updates about their vehicle's maintenance status. This creates a culture of proactive maintenance throughout your organization.

Choosing the Best CMMS Fleet Maintenance Software

Integration Capabilities

Your CMMS should play well with your existing systems. Look for software that integrates with your fuel management system, GPS tracking, accounting software, and parts suppliers. Seamless data flow eliminates double-entry and reduces errors.

Scalability Matters

Whether you manage 10 vehicles or 1,000, your CMMS should grow with your fleet. Cloud-based solutions typically offer the flexibility to add vehicles, users, and features as needed without major infrastructure investments.

User-Friendly Design

The most powerful software in the world won't help if your team won't use it. Choose a system with intuitive interfaces that require minimal training. Your technicians should focus on fixing vehicles, not fighting software.

Robust Support and Training

Even the best software occasionally needs help. Look for vendors that offer comprehensive training, responsive customer support, and regular software updates. Your CMMS partner should be invested in your success.

Getting Started: Your Next Steps

Implementing CMMS fleet maintenance software doesn't have to be overwhelming. Start by auditing your current maintenance processes and identifying your biggest pain points. Do vehicles sit too long waiting for parts? Are you constantly surprised by breakdowns? Is maintenance scheduling a constant headache?

Once you understand your challenges, you can evaluate CMMS solutions based on how well they address your specific needs. Most vendors offer demos or trial periods, so you can test-drive the software before committing.

The Bottom Line

CMMS fleet maintenance software isn't just another technology expense—it's an investment that pays for itself through reduced costs, improved efficiency, and better fleet reliability. In today's competitive business environment, you can't afford to manage your fleet maintenance with outdated methods.

The question isn't whether you can afford to implement CMMS software. It's whether you can afford not to. Every day you wait is another day of inefficient operations, unexpected breakdowns, and missed opportunities to optimize your fleet performance.

Your vehicles are critical business assets. Isn't it time you managed them like it?