Miya Bholat

Miya Bholat

Sep 18, 2025

How Mobile Vehicle Inspection Apps Transform Fleet Maintenance Management

Let’s face it, managing a fleet of vehicles and equipment used to mean crossing your fingers and hoping nothing broke down unexpectedly. Those days of reactive maintenance and costly surprises are quickly becoming a thing of the past, thanks to mobile vehicle inspection apps that are revolutionizing how fleet managers stay ahead of problems.

If you're still relying on paper checklists, phone calls, and direct conversations to manage your fleet's health, you're not just missing out on efficiency—you're likely hemorrhaging money on preventable repairs and downtime. Let's explore how mobile fleet inspection apps are changing the game for fleet managers and maintenance teams alike.

The Real Cost of Playing Vehicle Roulette

Before diving into solutions, let's talk about what's at stake. The average fleet vehicle experiences unexpected breakdowns that cost companies between $500 to $1,500 per incident when you factor in repair costs, towing, rental replacements, and lost productivity. Multiply that across a fleet of 50, 100, or 500 vehicles, and you're looking at budget-crushing expenses that could have been prevented.

Traditional inspection methods often fall short because they're inconsistent, time-consuming, and create communication gaps between drivers, fleet managers, and maintenance teams.

A driver might notice a strange noise on Monday, forget to mention it until Friday, and by then, what could have been a $200 brake pad replacement has turned into a $2,000 brake system overhaul. These are the scenarios you must avoid and ones that routine pre-trip inspections using mobile inspections apps can prevent.

Real-Time Issue Detection: Your Fleet's Early Warning System

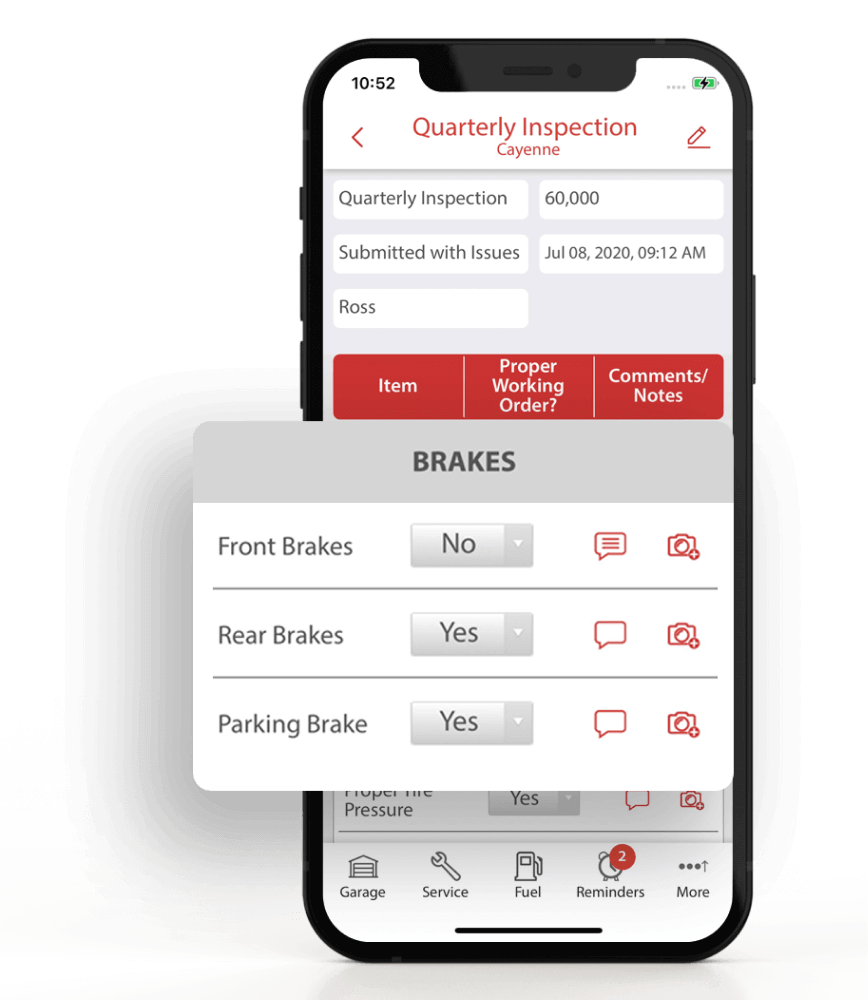

Mobile vehicle inspection apps transform every driver into a quality control inspector. Instead of hoping drivers remember to report issues, these apps guide them through standardized digital checklists that ensure nothing gets overlooked

Picture this: Your driver starts their pre-trip inspection and notices the left front tire looks low. With a mobile app, they can instantly photograph the tire, mark its location on a digital vehicle diagram, add notes about the severity, and submit the report—all in under two minutes. That information immediately appears on your dashboard, complete with GPS location, timestamp, and visual evidence.

This real-time visibility means you can make informed decisions quickly. Is it safe for the driver to complete their route? Should you dispatch a mobile repair service? Can it wait until the scheduled maintenance window? You have the information you need to choose the most cost-effective response instead of making expensive emergency decisions.

Breaking Down Communication Barriers

One of the biggest game-changers is how mobile inspection apps eliminate the telephone game between field staff and maintenance teams. Instead of relying on secondhand descriptions like "there's a weird noise coming from somewhere near the front," maintenance teams receive detailed reports with photos, exact locations, and standardized terminology.

This improved communication has several ripple effects. Maintenance teams can better prepare for repairs by ordering parts in advance, mechanics can diagnose issues more accurately before the vehicle arrives, and fleet managers can make informed decisions about whether repairs can wait or need immediate attention.

The result? Faster repairs, more accurate cost estimates, and significantly less back-and-forth communication that wastes everyone's time.

Transforming Maintenance from Reactive to Predictive

Perhaps the most valuable benefit of mobile inspection apps is how they enable predictive maintenance strategies. Instead of waiting for components to fail, you start building a historical database of your fleet's health patterns.

Over time, you begin to notice trends: vehicles that primarily drive highway routes need tire rotations every X miles, city delivery vehicles show brake wear patterns that suggest replacement every Y months, and certain vehicle models consistently develop specific issues around Z mileage intervals.

This data-driven approach allows you to schedule maintenance during planned downtime rather than dealing with emergency breakdowns during peak operational hours. The cost savings are substantial—planned maintenance typically costs 30-50% less than emergency repairs, and you avoid the productivity losses that come with unexpected vehicle unavailability.

Maximizing Vehicle Uptime and ROI

Every day a vehicle sits in the shop is a day it's not generating revenue or serving customers. Mobile inspection apps help maximize uptime in several ways:

Faster Diagnosis: Detailed reports with photos and standardized descriptions help mechanics identify issues quickly, reducing diagnostic time.

Better Parts Management: Advance notice of needed repairs allows for proactive parts ordering, eliminating delays waiting for components to arrive.

Optimized Scheduling: You can batch similar repairs, schedule maintenance during low-demand periods, and coordinate multiple services to minimize shop time.

Improved Planning: Real-time fleet health visibility helps you make smarter decisions about route assignments, backup vehicle deployment, and maintenance timing.

The cumulative effect is a fleet that spends more time on the road generating value and less time sitting idle in repair bays.

Digital Documentation: Your Compliance and Cost Recovery Ally

Paper inspection logs have a way of disappearing, getting damaged, or becoming illegible at the worst possible moments—like during DOT audits or insurance claims. Mobile inspection apps create permanent, searchable digital records that protect your company in multiple ways.

For compliance purposes, you have timestamped, GPS-verified proof that inspections were completed according to regulations. During insurance claims, detailed photos and maintenance records can help demonstrate that vehicle issues weren't due to negligence. When disposing of vehicles, comprehensive maintenance histories can increase resale values.

This documentation also helps with internal cost analysis. You can track which vehicles are expensive to maintain, identify patterns that suggest training needs, and make data-driven decisions about fleet composition and replacement schedules.

Safety: The Non-Negotiable Benefit

Beyond cost savings and efficiency gains, mobile vehicle inspection apps significantly improve safety outcomes. Standardized digital checklists ensure critical safety components—brakes, tires, lights, steering—are consistently evaluated by every driver on every shift.

When safety issues are identified and documented immediately, you can take appropriate action before they lead to accidents, injuries, or liability claims. This proactive approach protects your drivers, other road users, and your company's reputation and financial stability.

Making the Transition to Mobile Inspection Apps a Smooth Operation

The beauty of modern mobile inspection apps is their intuitive design. Most drivers can learn the basics in a few minutes, and the apps are designed to work offline when cellular coverage is spotty—a crucial feature for fleets operating in remote areas.

The key to successful implementation is focusing on the value proposition for drivers. When they understand that detailed inspections protect their safety and make their jobs easier (fewer breakdown delays, better-maintained vehicles), adoption becomes much smoother.

More importantly, these apps transform fleet management from a reactive, stress-inducing responsibility into a proactive, data-driven operation. Instead of wondering when the next expensive surprise will hit, you gain visibility and control over your fleet's health and costs.

Ready to Transform Your Fleet Management?

The question isn't whether mobile vehicle inspection apps like AUTOsist provide value—it's whether you can afford to continue managing your fleet without them. Every day you delay implementation is another day of preventable costs, safety risks, and operational inefficiencies.

Looking to implement mobile vehicle inspection technology for your fleet? Start a free trial of AUTOsist and request a demo to see how our fleet management software can improve your fleet operations and benefit your bottom line.