Miya Bholat

Miya Bholat

May 27, 2025

Why Preventive Maintenance Checklists and Schedules Are Essential for Fleet Operations

If you're running a fleet, you already know one thing for sure: when a vehicle goes down, it’s more than a mechanical issue—it’s a potential disruption to your entire organization’s operations. Staying ahead with preventive maintenance checklists and schedules isn’t just smart, it’s essential for fleet management.

In this post, we break down how consistent maintenance helps your operation run smoother, saves money, and keeps your drivers safer on the road.

The Benefits of Vehicle Preventive Maintenance Checklists

Your fleet is the heart and soul of your organization, and the longer vehicles stay in the shop, the less potential they have to serve and earn. Here’s what a solid preventive maintenance program can do for you and your organization:

1. Less Unplanned Downtime

When you’re regularly checking fluids, brakes, and tires, you catch small issues before they turn into major problems. Fewer surprise breakdowns mean fewer last-minute schedule changes or missed deliveries. Downtime kills productivity— and trust with customers.

2. Lower Repair Costs

Preventive maintenance costs a lot less than emergency repairs. Think of it like going to the doctor for a checkup instead of ending up in the ER. According to the U.S. Department of Energy, emergency repairs can cost 50% more than routine maintenance.

3. Longer Vehicle Lifespan

Want to squeeze every useful mile out of your vehicles? Regular maintenance helps prevent engine and transmission failures, which are some of the costliest repairs. That means you can delay replacement and get more value out of each asset.

4. Better Fuel Efficiency

Dirty air filters, underinflated tires, and old oil can make engines work harder than they need to. Just keeping your tires properly inflated can improve gas mileage by up to 3%, according to the U.S. EPA.

5. Maintain DOT Compliance

Fleet audits and roadside inspections go a lot smoother when your records are up to date and your vehicles are well-maintained. Preventive maintenance helps you pass those inspections and avoid costly fines and downtime for being put out-of-service.

What to include in a Preventive Maintenance Checklist?

If you’re looking to develop your own checklist, we have you covered. Here’s a quick example of what you might include on your standard checklist. Most of these should be done at regular mileage intervals or based on hours of operation:

Oil and filter changes

Brake inspection (pads, rotors, fluid)

Tire check (tread depth, pressure, rotation)

Lights and electrical systems

Cooling system inspection (hoses, belts, coolant)

Transmission fluid and filters

Battery and charging system

Windshield wipers and washer fluid

Suspension and steering components

Check for diagnostic trouble codes (DTCs)

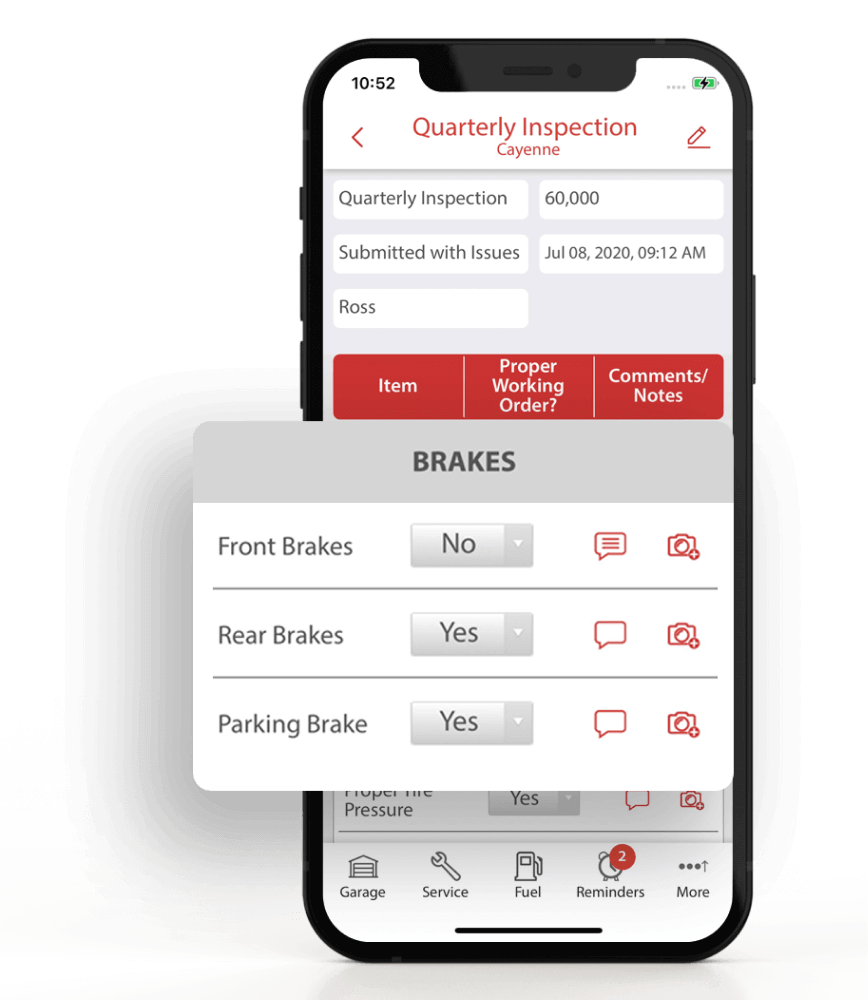

Tip: Use fleet maintenance software to automate these checklists, receive reminders for due soon maintenance, and log every service for compliance and resale purposes.

What Happens If You Skip or Delay Fleet Vehicle Maintenance?

Let’s face it, the purpose of maintaining your vehicles is to extend both the time they spend on the road serving your customers, and the entirety of its lifespan. If you push off maintenance, or miss one too many oil changes, here is the economic reality:

Experienced a blown transmission? That will run you about $3,000–$5,000, according to RepairPal.

Did brake failure lead to an accident? Those fleet insurance claims and liability can exceed $10,000+.

Need tow and roadside assistance when broken down? It will cost about $150–$300 per tow depending on mileage traveled.

Lost productivity while a vehicle is down or in the shop unplanned? Easily $250–$1,000 each day depending on the job.

That also doesn’t include the potential customer impact costs—missed deliveries, lost contracts, or drivers sitting idle. Preventive maintenance costs about $500–$700 per vehicle per year, according to fleet industry averages and fleet maintenance software like AUTOsist is as low as $5 per vehicle a month. It’s an investment that pays for itself.

Set Up a Preventive Maintenance Schedule That Works

The key is to build a schedule around your fleet’s duty cycles—think mileage, hours of operation, and load types. A light-duty delivery van doing 200 miles a day will need different care than a Class 8 truck hauling heavy loads across the country.

Consider breaking your maintenance schedule into these categories:

Pre-trip inspections: Performed routinely by drivers via a fleet management app.

PM Schedule 1: (every 5,000–7,000 miles): Basic checks—oil, filters, tires, fluids.

PM Schedule 2: (every 15,000–25,000 miles): Deeper inspections—brakes, suspension, diagnostics.

PM Schedule 3: (every 50,000–75,000 miles): Comprehensive overhaul—transmission service, alignment, coolant flush, etc

By sticking to a preventive maintenance schedule, your fleet stays on the road longer and out of the shop. Fleet maintenance software like AUTOsist allows you to customize maintenance schedules to each vehicle, and you get notifications when maintenance is due soon.

If you're not running a structured preventive maintenance program, now’s the time to start. It’s not just about saving money in your budget (though you certainly will). It’s about creating a fleet that’s safer, more efficient, and more reliable—for your drivers and your customers.

Downloadable Fleet Preventive Maintenance Checklist (Sample)

Need a preventative maintenance checklist to help you get started?

Here’s a Preventive Maintenance Checklist you can customize to your fleet.

Of course, if you’re ready to move off the spreadsheet and into an automated system for managing preventive fleet maintenance, consider starting a free trial of AUTOsist.