Miya Bholat

Miya Bholat

Jan 17, 2026

When Does a Vehicle Need Alignment? Signs, Costs, and Fleet Scheduling Guide

Fleet vehicles take more abuse than personal cars. They hit potholes, carry heavy loads, rack up miles quickly, and often operate on tight schedules where small issues get ignored. Wheel alignment is one of those issues. When it’s off, the symptoms start subtle, but the costs add up fast—especially across a fleet.

This guide breaks down how to recognize alignment problems early, why alignment matters financially and operationally, and how fleet managers can build alignment checks into a preventive maintenance strategy instead of reacting after tires are already ruined.

Key Takeaways: Keeping Your Fleet Vehicles Properly Aligned

- Early warning signs matter. Pulling, vibration, and uneven tire wear should trigger inspections before costs escalate.

- Misalignment is a cost multiplier. Tire wear, fuel loss, and downtime often outweigh the cost of alignment service itself.

- Schedule alignment proactively. Mileage-based and event-triggered checks prevent reactive maintenance.

- Track alignment consistently. Service history reveals problem vehicles and helps optimize PM schedules.

- Prevention saves money. Driver habits, inspections, and load management reduce repeat alignment issues.

How to Tell When a Vehicle Needs Alignment

Wheel alignment problems rarely show up as a single dramatic failure. Instead, they creep in through handling changes, uneven tire wear, and driver complaints that are easy to dismiss if you’re not watching closely. For fleet managers, the key is spotting patterns across vehicles before alignment issues turn into tire replacements or safety incidents.

Misalignment affects how the tires contact the road. Even small deviations can cause excessive friction, unstable steering, and accelerated wear. Because fleet vehicles often run long routes or repeat the same roads, alignment issues can worsen quickly if they’re not addressed early.

Visual Inspection Signs

A quick walkaround can reveal early alignment problems if you know what to look for. Maintenance teams should be trained to scan for these during routine checks.

Common visual clues include:

- Steering wheel sitting off-center when the wheels are straight

- Tires that appear tilted inward or outward when viewed head-on

- Uneven gaps between tires and wheel wells

- Rapid tire shoulder wear compared to the center tread

These signs don’t always confirm alignment issues on their own, but they’re strong indicators that a closer inspection is needed—especially if multiple vehicles show similar symptoms.

Driver-Reported Symptoms

Drivers are often the first to feel alignment problems, but they may not always describe them accurately. Encourage drivers to report handling changes, not just obvious mechanical failures.

Typical driver-reported symptoms include:

- Vehicle pulling to one side on a straight road

- Steering wheel vibration at highway speeds

- Steering wheel not returning to center after turns

- Increased effort needed to keep the vehicle straight

When several drivers report similar feedback on the same route or vehicle type, alignment should be high on your diagnostic checklist.

Tire Wear Patterns That Signal Misalignment

Tire wear tells the most reliable story. Alignment issues create distinct wear patterns that experienced technicians can spot immediately.

Watch for:

- Inside or outside edge wear: Often caused by camber misalignment

- Feathered tread edges: Usually a toe alignment problem

- Uneven wear across axle pairs: Indicates alignment drift or suspension wear

Catching these patterns early can save hundreds of dollars per vehicle in tire costs alone.

Why Proper Wheel Alignment Matters for Fleet Vehicles

Alignment isn’t just about driver comfort. For fleets, it directly impacts safety, operating costs, and vehicle uptime. Ignoring alignment issues can quietly erode budgets and increase risk exposure.

Safety and Liability Concerns

Misaligned vehicles don’t handle predictably. Pulling, drifting, or unstable steering increases driver fatigue and reduces reaction time in emergencies. In high-mileage fleets, even a slight alignment issue can increase stopping distance and reduce tire grip during braking or cornering.

From a liability standpoint, worn or uneven tires raise red flags during accident investigations. Poor maintenance records can work against fleet operators if alignment-related wear contributed to a collision. Regular alignment checks help demonstrate due diligence and commitment to vehicle safety.

The Real Cost of Misalignment

Alignment issues often cost more indirectly than directly. A typical alignment service may cost $100–$200, but skipping it can trigger a chain reaction of expenses.

Misalignment can lead to:

- Tire life reduced by 25–50%

- Increased fuel consumption due to rolling resistance

- Premature suspension component wear

- Unplanned downtime for tire replacement

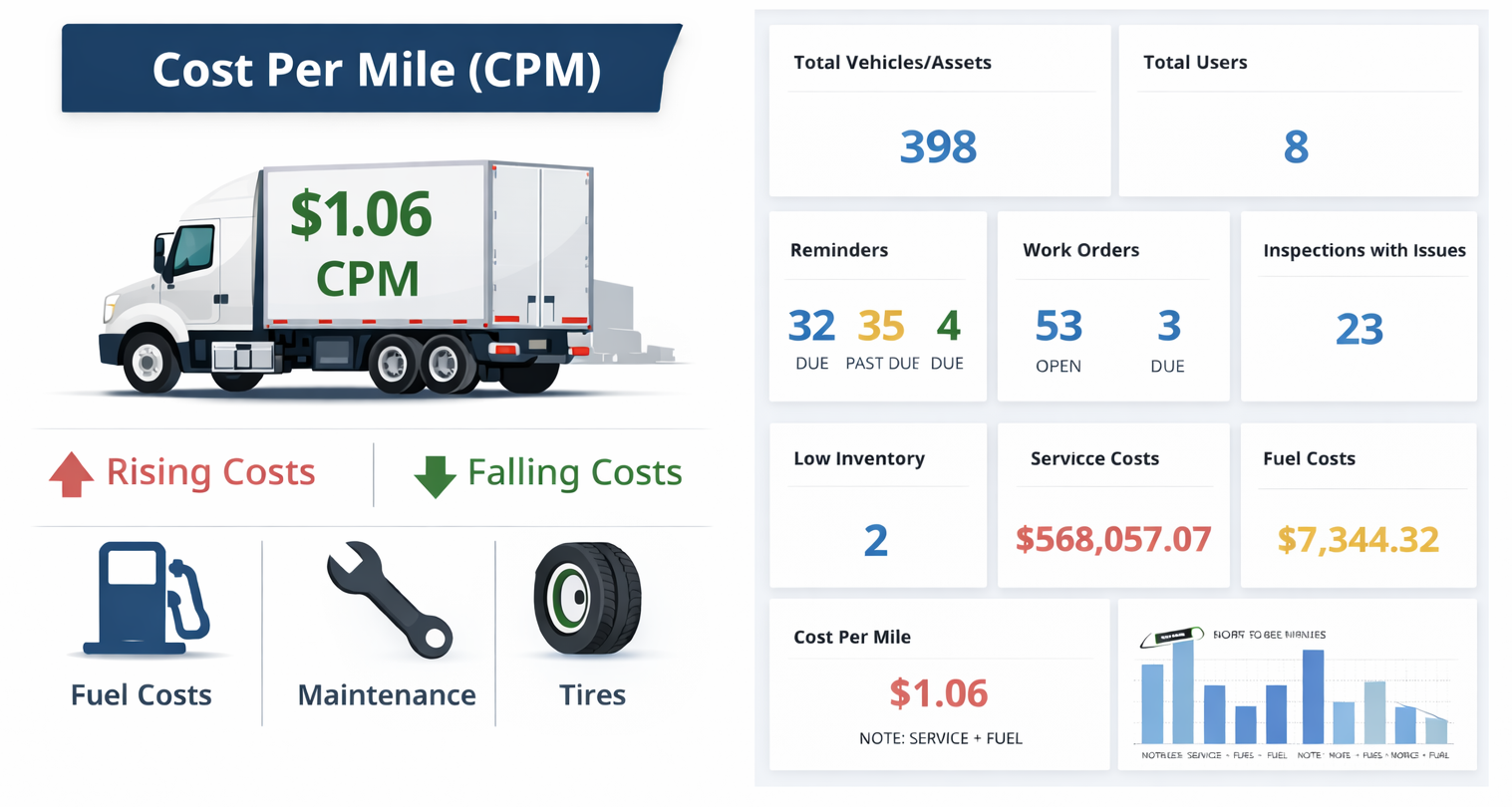

Across a fleet of 25–50 vehicles, these costs compound quickly. Tracking alignment as part of a broader maintenance strategy—alongside services like inspections and work orders—helps control these expenses. Many fleets use systems like fleet maintenance work order software to document alignment services and tie them to tire replacements and suspension repairs.

What Causes Vehicles to Fall Out of Alignment

Fleet vehicles face harsher conditions than personal vehicles, which is why alignment issues are more common in commercial operations. Understanding the causes helps managers reduce repeat problems.

The most common contributors include:

- Potholes and rough roads: A single impact can knock alignment out instantly

- Curb strikes: Common in delivery and service fleets

- Heavy or uneven loads: Especially in construction and utility fleets

- Normal suspension wear: Bushings, ball joints, and control arms degrade over time

Repeated exposure to the same routes can also play a role. Vehicles that operate in urban environments with frequent stops, tight turns, and uneven pavement are more prone to alignment drift than highway-only units.

When to Schedule Alignment Checks

Waiting until tires are visibly worn is too late. Fleet alignment checks should be proactive, not reactive. Clear scheduling rules help maintenance teams stay consistent.

Mileage-Based Intervals

Many fleets schedule alignment checks based on mileage, especially for high-use vehicles.

Common benchmarks include:

- Every 12,000–15,000 miles for light-duty fleet vehicles

- Every tire replacement or rotation

- More frequently for vehicles carrying heavy loads

Mileage-based reminders are easier to manage when alignment checks are tied into broader preventive maintenance workflows. Tools like fleet preventive maintenance schedules and reminders help ensure alignment checks don’t get skipped.

Event-Triggered Alignments

Certain events should trigger immediate alignment inspections, regardless of mileage.

These include:

- Pothole or curb impacts

- Accidents or near-miss incidents

- Suspension repairs or component replacements

Documenting these events alongside service history helps identify vehicles that repeatedly fall out of alignment due to route conditions or usage patterns.

Integrating Alignment into PM Schedules

Alignment works best when treated as part of a larger preventive maintenance plan, not a standalone service. Many fleets bundle alignment checks with inspections, tire rotations, or brake service.

Tracking these services centrally using a vehicle service history system makes it easier to spot trends—such as certain vehicles needing alignment more often than others.

What Happens During a Wheel Alignment Service

For many fleet managers, alignment feels like a black box. Understanding what technicians actually do helps justify the time and cost.

During an alignment, technicians measure three primary angles:

- Camber: Inward or outward tilt of the wheel

- Caster: Steering axis angle affecting stability

- Toe: Direction tires point relative to the vehicle centerline

Using computerized alignment equipment, technicians compare measurements to manufacturer specifications and adjust suspension components as needed. Most alignments take 45–90 minutes, depending on vehicle type and condition.

Costs typically range from $100–$200 per vehicle, with higher costs for heavy-duty trucks or vehicles requiring additional suspension work.

Preventing Alignment Issues in Fleet Vehicles

Prevention is where fleets see the biggest savings. While alignment issues can’t be eliminated entirely, they can be reduced significantly with the right practices.

Key preventive strategies include:

- Training drivers to avoid curbs, potholes, and aggressive cornering

- Maintaining proper tire inflation to reduce uneven stress

- Performing regular suspension inspections

- Managing loads to avoid excessive front or rear axle stress

Proactive maintenance tracking makes these strategies easier to enforce. Many fleets rely on digital inspections and dashboards to catch early warning signs before they escalate.

Tracking Alignment Service in Your Fleet Maintenance Program

Alignment data becomes valuable when it’s tracked consistently. Recording alignment services helps identify problem vehicles, routes, or drivers contributing to repeat issues.

A strong tracking approach includes:

- Logging alignment services alongside tire replacements

- Monitoring alignment frequency by vehicle or route

- Identifying high-cost units that may need suspension upgrades

Using maintenance software allows fleet managers to connect alignment data with mileage, inspections, and fuel efficiency. Over time, patterns emerge that support better decision-making—whether that means changing routes, upgrading components, or adjusting maintenance intervals.

Keeping your fleet properly aligned isn’t just good maintenance—it’s smart fleet economics.