Fleet Maintenance Guides

Fleet Inventory & Parts Management Software

Fleet inventory and parts management software provides structured control over parts, consumables, and components used in vehicle and equipment maintenance.

GPS Tracking for Fleet Management

GPS tracking for fleet management uses location-based telematics data to monitor vehicles, drivers, and equipment in real time, enabling operational visibility, performance control, and compliance documentation across fleet operations.

Fleet Telematics & Maintenance Integration Guide

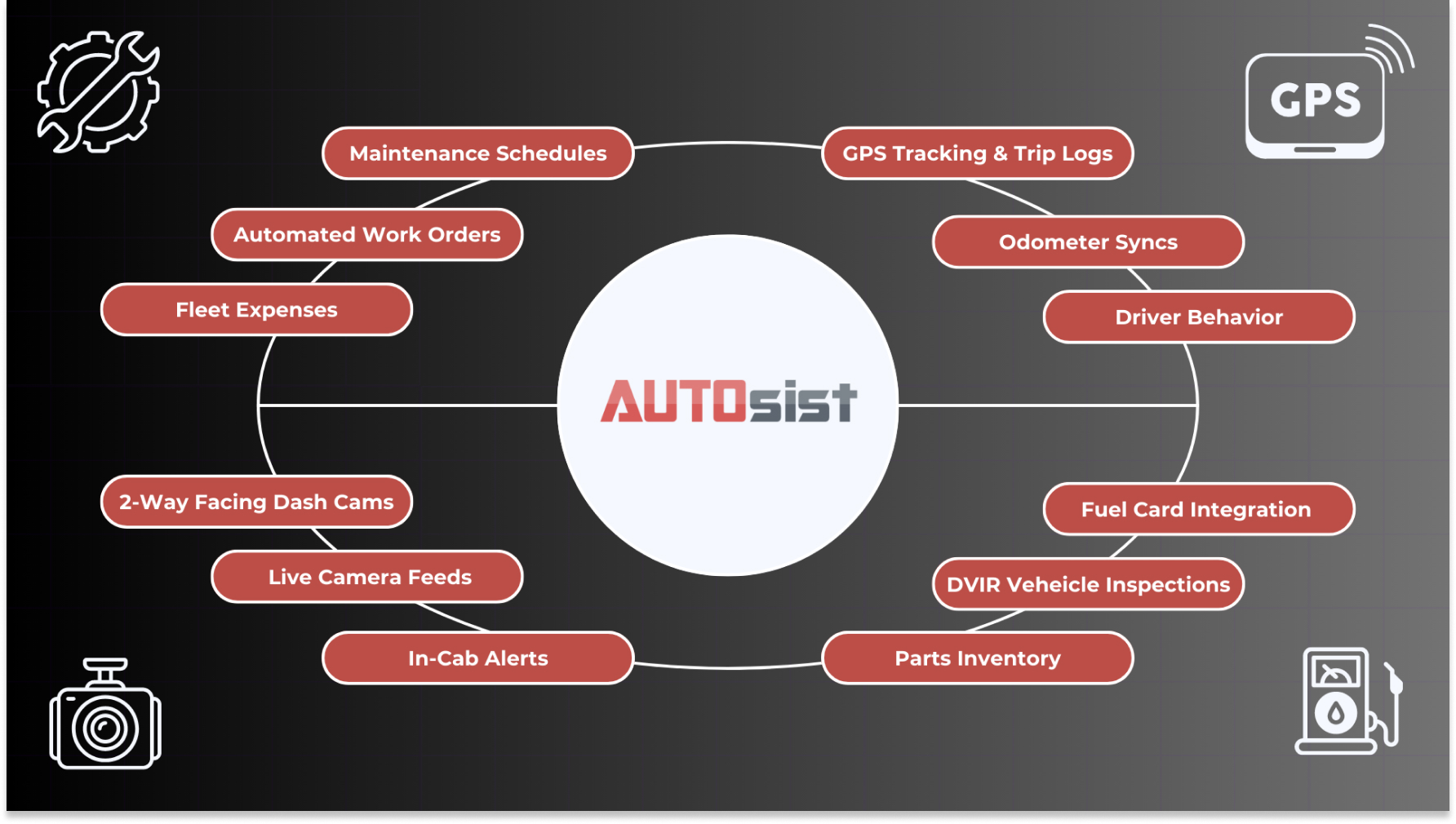

Fleet telematics integration connects vehicle tracking data with maintenance, compliance, and operational systems to create a unified view of fleet performance. When structured correctly, integration enables preventive maintenance automation, compliance visibility, and data-driven operational control.

Work Order Management Software for Fleets

Work order management software for fleets is a structured digital system used to create, assign, track, and close maintenance tasks across vehicles and equipment.

Fleet Inspection Software Guide

Fleet inspection software is a digital system used to standardize, document, and manage vehicle inspections across a fleet. It supports compliance, reduces operational risk, and ensures inspection findings translate into corrective maintenance actions.

Preventive Maintenance Scheduling Software for Fleets

Preventive maintenance scheduling software for fleets is a structured system that automates service intervals based on time, mileage, engine hours, or other usage data.

Fleet Management Software Buyer's Guide

A fleet management software buyer's guide provides a structured framework for evaluating platforms that support maintenance, compliance, cost control, and operational visibility.

Fleet Maintenance Software Buyer's Guide

A fleet maintenance software buyer's guide provides a structured framework for evaluating systems that manage preventive maintenance, work orders, inspections, and compliance across fleet operations.

Best Fleet Maintenance Software (2026 Comparison Guide)

Fleet maintenance software in 2026 must do more than track service dates; it must coordinate preventive schedules, inspections, work orders, inventory, reporting, and integrations in one operational system.

Best Fleet Management Software (2026 Comparison Guide)

Fleet management software centralizes maintenance, compliance, tracking, reporting, and cost control into a structured operating system.

Fleet Safety Monitoring

Fleet safety monitoring is the ongoing process of observing vehicles, drivers, maintenance status, and operational behaviors to reduce risk, maintain compliance, and prevent avoidable incidents.

Diagnostic Trouble Codes (DTC) Guide

Diagnostic Trouble Codes (DTCs) are standardized fault indicators generated by vehicle onboard diagnostic systems to signal potential mechanical, electrical, or emissions-related issues.

Asset Lifecycle Management for Fleet Operations

Asset lifecycle management in fleet operations is the structured process of planning, tracking, maintaining, and retiring vehicles and equipment based on cost, performance, and compliance data. When managed consistently, it reduces downtime, stabilizes budgets, and improves long-term operational reliability.

Lease or Buy Fleet Vehicles: Operational Decision Guide for Fleet Managers

Choosing whether to lease or buy fleet vehicles affects long-term cost control, maintenance planning, asset visibility, and replacement cycles. The decision is operational rather than purely financial, requiring evaluation of usage patterns, maintenance capacity, and lifecycle data.

Fleet Telematics Explained: Complete Integration Guide

Fleet telematics refers to the combined use of GPS devices, vehicle sensors, and data platforms to capture real-time and historical information about vehicles, drivers, and assets.

Dash Cam Benefits for Fleets

Fleet dash cameras are vehicle-mounted video systems that capture driving activity and road conditions to improve safety oversight, incident documentation, and operational accountability across fleet vehicles.

Diesel Fleet Maintenance Checklist: Complete Guide

A diesel fleet maintenance checklist is a structured reference used to standardize inspections, service intervals, and defect tracking for diesel-powered vehicles and equipment.

PM Intervals for Mixed Fleets: Hours vs Miles Guide

Preventive maintenance (PM) intervals in mixed fleets must reflect how assets actually wear, not just how they are categorized.

Vehicle Safety Inspection: Complete 2026 Fleet Guide

Vehicle safety inspections are structured evaluations of a fleet vehicle’s mechanical condition, safety systems, and regulatory compliance status.

Multi-Location Fleet Inspections: Management Guide

Multi-location fleet inspections refer to the process of applying consistent inspection standards, schedules, and defect controls across multiple depots, branches, or operating sites.

Farm Equipment Maintenance Guide for Fleet Operations

Farm equipment maintenance is the structured process of inspecting, servicing, and documenting agricultural machinery to maintain reliability, safety, and operational continuity.

Fleet Budget Template: Annual Planning Guide

A fleet budget template is a structured framework used to forecast, allocate, and monitor all vehicle-related costs over a 12-month period. Consistent annual planning supports cost control, maintenance readiness, and compliance stability across the fleet.

Fleet Safety Guide for Fleet Operations

Fleet safety refers to the structured policies, inspections, maintenance controls, and driver practices used to reduce vehicle incidents, injuries, and compliance violations.

Fleet Efficiency in Fleet Operations

Fleet efficiency refers to how effectively vehicles, drivers, maintenance resources, and operational processes are used to achieve business goals with minimal waste.

How to Improve Fleet Management

Improving fleet management requires consistent control over maintenance, utilization, safety, and data visibility. Structured processes and measurable performance indicators enable fleets to reduce downtime, control operating costs, and maintain regulatory readiness across vehicles and teams.

Fleet Optimization

Fleet optimization is the structured process of aligning vehicles, maintenance activities, utilization levels, and operational data to achieve lower operating costs, higher asset availability, and predictable service performance.

When Fleet Maintenance Software Fails (And Why)

Fleet maintenance software failure does not usually mean the system stops working; it typically means the fleet stops using it correctly or consistently. When adoption, configuration, or data discipline breaks down, operational visibility declines, compliance exposure increases, and maintenance decisions revert to guesswork.

GPS Tracking for Fleets: OBD vs Wired Installation Guide

GPS tracking installation method directly affects data reliability, vehicle downtime, and long-term device performance. Choosing between OBD plug-in devices and wired trackers is an operational decision that influences maintenance records, mileage accuracy, and fleet visibility consistency.

Preventive Maintenance Schedule Template

A preventive maintenance schedule template is a structured document used to plan, record, and control recurring vehicle and equipment service activities. In fleet operations, it supports consistency, compliance readiness, cost predictability, and asset lifespan management.

Vehicle Inspection Checklist

A vehicle inspection checklist is a structured method used by fleet teams to verify vehicle safety, compliance, and operational readiness before and after use, as well as during scheduled maintenance cycles. Consistent inspections reduce breakdown risk, support regulatory compliance, and create traceable maintenance records for operational decision-making.

How to Prepare for a DOT Fleet Audit

A DOT fleet audit is a formal review of a fleet’s safety, maintenance, driver, and compliance records conducted by regulatory authorities. Proper preparation reduces the risk of fines, operational delays, and out-of-service violations while ensuring documentation accuracy and process consistency.

Hidden Cost of Poor Fleet Maintenance

Poor fleet maintenance does not only increase repair expenses; it creates indirect operational, safety, administrative, and asset-lifecycle costs that are often untracked. These hidden costs accumulate gradually and can exceed visible maintenance spend if preventive controls, documentation, and scheduling discipline are inconsistent.

Fleet Maintenance KPIs (With Formulas)

Fleet maintenance KPIs are measurable performance indicators used to evaluate vehicle reliability, maintenance efficiency, and cost control. Tracking these indicators enables fleet teams to make evidence-based operational decisions, reduce unplanned downtime, and maintain consistent service standards across vehicles and equipment.

Fleet Maintenance Audit Checklist

A fleet maintenance audit checklist is a structured method used to verify whether vehicles, maintenance processes, documentation, and compliance controls are operating as intended. Regular audits help fleets identify gaps early, reduce operational risk, and maintain consistent safety and cost control standards.

DOT Fleet Maintenance Requirements Explained

DOT fleet maintenance requirements establish the minimum standards fleets must follow to ensure vehicles are safe, inspected regularly, repaired promptly, and supported by verifiable records. For fleet managers and maintenance teams, these rules are less about paperwork and more about maintaining consistent vehicle condition, operational safety, and audit-ready proof of compliance.

How Long to Keep Fleet Maintenance Records

Fleet maintenance record retention refers to how long organizations keep inspection logs, repair histories, compliance documents, and service data for each vehicle or asset. Clear retention timelines support regulatory compliance, audit readiness, dispute resolution, and long-term operational decision-making.

Best Fleet Maintenance Software for Small Fleets

Fleet maintenance software for small fleets refers to systems designed to track, schedule, and document vehicle maintenance with minimal administrative overhead. For fleets with limited staff and growing vehicle counts, structured maintenance software reduces missed services, improves visibility, and supports consistent operational control.

Fleet Maintenance SOP Guide

A Fleet Maintenance Standard Operating Procedure (SOP) is a structured document that defines how vehicle maintenance activities are planned, executed, recorded, and reviewed. It ensures consistency, accountability, compliance readiness, and predictable operational uptime across all fleet assets.

Fleet Compliance Guide

Fleet compliance is the ongoing process of meeting regulatory, safety, and operational requirements that govern how fleet vehicles, drivers, and maintenance activities are managed. For fleet managers, compliance is not a one-time task but a continuous operational responsibility that directly affects safety outcomes, audit readiness, and business risk.

Vehicle Inspection Guide

Vehicle inspections are a structured process used by fleets to verify vehicle safety, condition, and compliance before, during, and after operation. For fleet managers, inspections reduce risk, support regulatory compliance, and provide early visibility into maintenance issues that affect uptime and operating cost.

Preventative Maintenance Guide for Fleet Operations

Preventative maintenance is a structured approach to servicing fleet vehicles at planned intervals to reduce breakdowns, control costs, and maintain compliance. For fleet operations, it is a core operational discipline that directly affects vehicle uptime, safety outcomes, and long-term asset value.

Fleet Manager Guide

A fleet manager is responsible for keeping vehicles operational, compliant, and cost-controlled while supporting daily business operations. This guide outlines the core responsibilities, systems, and decision frameworks fleet managers rely on to maintain consistency, reduce risk, and improve fleet performance.

How to Track Fleet Maintenance (Step-by-Step)

Tracking fleet maintenance is the process of systematically recording, monitoring, and reviewing all maintenance activities across vehicles to support reliability, safety, cost control, and compliance. For fleet operations, a step-by-step tracking approach reduces missed service, improves decision-making, and creates a consistent maintenance record that can be audited and acted on.

Fleet Maintenance vs. Fleet Management Guide

Fleet maintenance and fleet management are closely related but operationally distinct disciplines. Understanding how they differ—and where they overlap—helps fleet teams select the right systems, assign responsibility correctly, and avoid gaps in vehicle uptime, cost control, and compliance.

What Is Fleet Maintenance Software

Fleet maintenance software is a digital system used to plan, track, and document vehicle maintenance activities across a fleet. It matters operationally because it centralizes maintenance data, standardizes processes, and helps fleet teams reduce downtime, control costs, and maintain compliance.