How Long to Keep Fleet Maintenance Records

Fleet maintenance record retention refers to how long organizations keep inspection logs, repair histories, compliance documents, and service data for each vehicle or asset. Clear retention timelines support regulatory compliance, audit readiness, dispute resolution, and long-term operational decision-making.

Fleet Maintenance Record Types and Suggested Retention Ranges

| Record Type | Legal Minimum | Recommended Duration | Primary Use |

|---|---|---|---|

| Driver Vehicle Inspection Reports (DVIR) | 3 months | 12–24 months | Safety verification |

| Repair & Work Orders | Varies by region | 3–5 years | Liability protection |

| Preventive Maintenance Logs | Not always specified | 3–7 years | Asset lifecycle tracking |

| Parts & Inventory Records | Not always specified | 2–4 years | Cost control |

| Compliance & Certification Documents | 1–3 years | 5+ years | Regulatory audits |

Retention requirements vary by jurisdiction and vehicle class. Fleets should verify regional transportation authority rules and insurance policy conditions.

Minimum Legal Retention vs. Extended Operational Retention

Minimum Legal Retention

- Meets baseline regulatory obligations only

- Often limited to inspections and safety documentation

- Focused on avoiding penalties rather than operational insight

- May not support warranty claims or long-term dispute resolution

Extended Operational Retention

- Preserves multi-year maintenance and cost trends

- Supports resale value and asset valuation discussions

- Enables insurance and legal defense documentation

- Improves forecasting, budgeting, and lifecycle planning

Regulatory and Legal Record Retention Requirements

Regulatory bodies typically define minimum retention periods for safety inspections, driver reports, and certain compliance documents. These minimums are often short and designed to confirm recent operational safety rather than long-term performance history.

Before establishing a retention policy, fleets should review transportation authority rules, insurance agreements, and contractual obligations. Requirements may differ for commercial vehicles, passenger transport, hazardous materials carriers, or government fleets.

Practical considerations include:

- Jurisdiction-specific transportation regulations

- Insurance policy documentation clauses

- Contractual obligations with clients or municipalities

- Vehicle class and usage type distinctions

Outcome focus:

- Avoid regulatory penalties

- Maintain defensible audit trails

- Ensure documentation validity during inspections

Categories of Fleet Maintenance Records

Fleet maintenance documentation extends beyond inspections and repairs. A complete retention policy identifies each record category and assigns an appropriate duration based on operational and compliance needs.

Common record categories include:

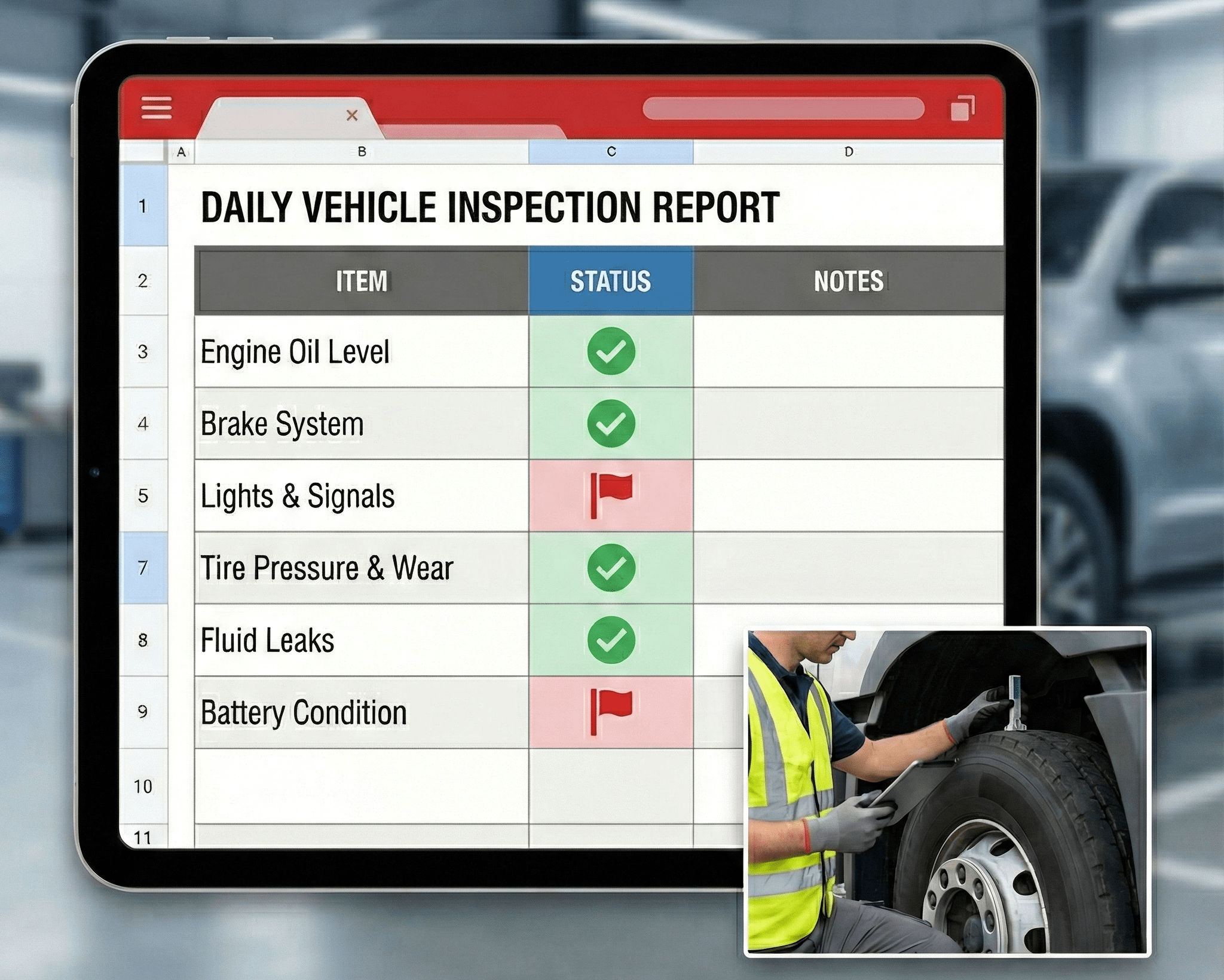

- Driver Vehicle Inspection Reports (pre-trip and post-trip)

- Repair invoices and technician work orders

- Preventive maintenance schedules and completion logs

- Parts purchase and inventory usage records

- Fuel and mileage tracking logs

- Compliance certificates, permits, and registrations

- Warranty and recall documentation

Outcome focus:

- Standardized documentation practices

- Reduced information gaps during audits

- Improved traceability across asset lifecycles

Recommended Retention Durations by Record Type

While legal minimums provide a baseline, many fleets adopt longer retention periods to protect against delayed claims, resale disputes, and long-term trend analysis. Extending retention also improves data continuity when vehicles change ownership internally or externally.

Typical operational ranges used by fleets:

- Inspections and DVIRs: 12–24 months

- Repairs and work orders: 3–5 years

- Preventive maintenance logs: 3–7 years

- Parts and inventory transactions: 2–4 years

- Compliance and certification files: 5+ years

Outcome focus:

- Stronger liability protection

- Better resale and valuation documentation

- Historical cost and performance visibility

Storage, Accessibility, and Audit Preparedness

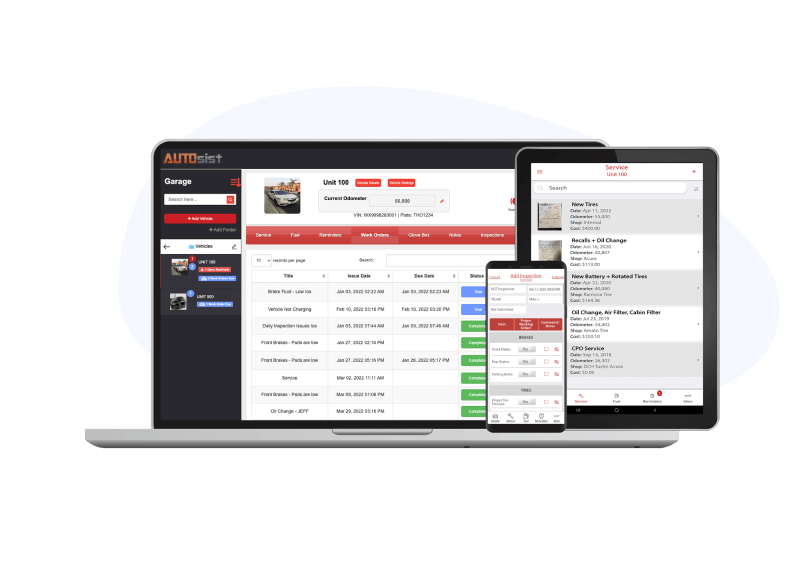

Record retention effectiveness depends on how documentation is stored and retrieved. Paper archives may satisfy minimum compliance but often create delays during inspections or internal reviews. Digital systems provide faster searchability, permission controls, and backup redundancy.

A practical retention policy defines both duration and storage method to ensure records remain intact and accessible throughout the chosen timeframe.

Operational storage practices include:

- Centralized record repositories rather than vehicle-level silos

- Role-based access controls for maintenance, compliance, and finance teams

- Automated backups and version tracking

- Consistent file naming and categorization standards

- Rapid retrieval capability during audits or roadside inspections

Outcome focus:

- Reduced audit preparation time

- Lower risk of document loss or duplication

- Improved cross-team visibility

Final Takeaways

A fleet maintenance record retention policy balances regulatory minimums with operational realities. Keeping records longer than legally required often provides measurable risk reduction and performance insight.

- Define retention timelines by record category, not a single blanket rule.

- Verify regional transportation and insurance requirements regularly.

- Extend retention for repairs, preventive maintenance, and compliance files.

- Centralize documentation to reduce audit delays and data gaps.

- Review retention policies annually as fleet size and regulations change.

AUTOsist Fleet Management Resources

Fleet Compliance Guide

Vehicle Inspection Guide

Daily DVIR Vehicle Inspection Checklist PDF

AUTOsist Fleet Maintenance Software