How to Improve Fleet Management

Improving fleet management requires consistent control over maintenance, utilization, safety, and data visibility. Structured processes and measurable performance indicators enable fleets to reduce downtime, control operating costs, and maintain regulatory readiness across vehicles and teams.

Utilization vs Cost Control Matrix

| Utilization Level | Risk Exposure | Recommended Action | Expected Outcome |

|---|---|---|---|

| Low | Asset Underuse | Reallocate or downsize units | Reduced fixed costs |

| Moderate | Balanced Wear | Maintain standard PM intervals | Stable operating cost |

| High | Accelerated Wear | Increase inspection frequency | Controlled failure risk |

| Very High | Breakdown Risk | Plan early replacement | Improved uptime |

| Seasonal Spikes | Maintenance Gaps | Adjust service schedules | Consistent availability |

Reactive Fleet Operations vs Proactive Fleet Management

Reactive Fleet Operations

- Maintenance triggered by breakdowns

- Limited visibility into asset condition

- Higher emergency repair costs

- Increased unplanned downtime

Proactive Fleet Management

- Scheduled preventive maintenance cycles

- Continuous inspection and defect tracking

- Predictable repair budgeting

- Improved uptime and asset lifespan

Establish Clear Fleet Objectives and Performance Metrics

Defining measurable operational goals provides a baseline for improvement and enables data-driven decision-making across maintenance, finance, and operations teams.

- Define cost-per-mile and maintenance-per-vehicle benchmarks

- Track vehicle availability and downtime ratios

- Measure inspection completion rates

- Monitor fuel efficiency and utilization levels

- Align departmental targets with overall fleet KPIs

Outcome

- Consistent performance measurement

- Faster identification of inefficiencies

- Clear accountability across teams

Strengthen Preventive Maintenance and Inspection Controls

Structured maintenance planning reduces unplanned failures and improves compliance documentation readiness. Consistency is more impactful than frequency alone.

- Implement mileage- and time-based service schedules

- Standardize inspection checklists across vehicle classes

- Record defect identification and correction timelines

- Maintain parts and service history logs

- Review maintenance trends quarterly

Outcome

- Reduced breakdown frequency

- Extended asset life

- Improved audit readiness

Optimize Vehicle Utilization and Asset Lifecycle Decisions

Balancing fleet size with operational demand prevents both asset underuse and excessive wear. Lifecycle planning should be based on operational data rather than age alone.

- Monitor utilization percentages per unit

- Evaluate replacement timing using repair trends

- Compare lease versus ownership costs

- Adjust fleet size based on seasonal demand

- Analyze cost-per-mile against depreciation curves

Outcome

- Lower total cost of ownership

- Improved resource allocation

- Predictable capital planning

Improve Driver Practices, Safety, and Accountability

Driver behavior directly influences fuel consumption, maintenance frequency, and incident risk. Structured training and monitoring programs create measurable improvements.

- Conduct recurring safety and compliance training

- Track incident and violation histories

- Encourage pre- and post-trip inspections

- Establish clear reporting channels for defects

- Align incentives with safe driving metrics

Outcome

- Reduced accident frequency

- Lower insurance and repair costs

- Stronger compliance posture

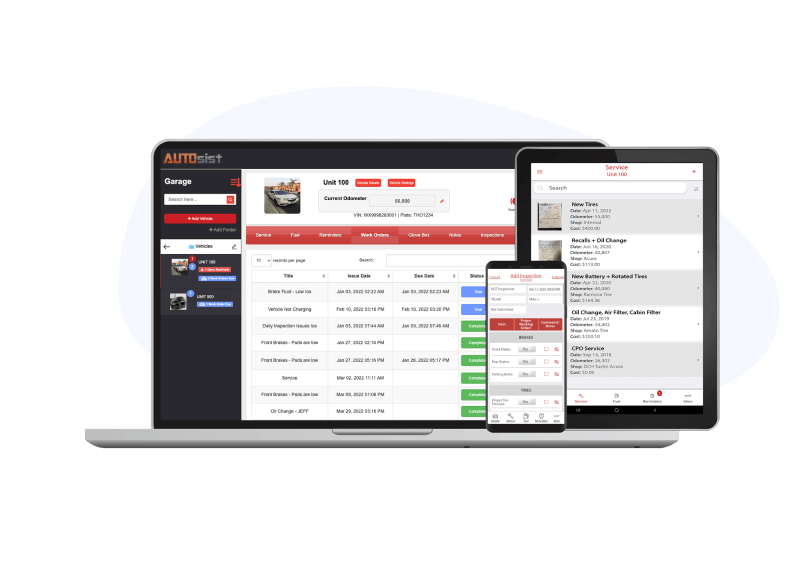

Centralize Data, Reporting, and Decision Workflows

Fragmented spreadsheets and paper logs limit visibility and delay corrective action. Centralized digital records enable faster planning, reporting, and audit preparation.

- Consolidate maintenance, inspections, and fuel data

- Automate service reminders and alerts

- Generate standardized performance reports

- Maintain digital audit trails

- Provide controlled access across departments

Outcome

- Faster decision cycles

- Improved record accuracy

- Consistent documentation standards

Final Takeaways

Improving fleet management is a continuous operational process that combines structured maintenance, measurable metrics, utilization control, and centralized data practices.

- Define and monitor KPIs consistently across departments.

- Maintain preventive maintenance and inspection discipline.

- Balance utilization with lifecycle replacement planning.

- Strengthen driver accountability and safety controls.

- Centralize operational data to improve visibility and audits.

AUTOsist Fleet Management Resources

Fleet Maintenance Audit Checklist

Vehicle Inspection Checklist

Preventive Maintenance Schedule Template

Fleet Maintenance Software