How to Track Fleet Maintenance (Step-by-Step)

Tracking fleet maintenance is the process of systematically recording, monitoring, and reviewing all maintenance activities across vehicles to support reliability, safety, cost control, and compliance. For fleet operations, a step-by-step tracking approach reduces missed service, improves decision-making, and creates a consistent maintenance record that can be audited and acted on.

Fleet Maintenance Tracking Components

| Component | Purpose | Data Source | Tracking Frequency |

|---|---|---|---|

| Vehicle profile | Identify asset and specs | Fleet records | Once, updated as needed |

| Service events | Record completed work | Maintenance logs | Per event |

| Preventive schedules | Plan recurring service | OEM guidelines | Ongoing |

| Inspections | Identify issues early | Driver or technician | Daily or periodic |

| Costs and downtime | Measure financial impact | Invoices and labor | Per event |

Manual Tracking vs Digital Tracking

Manual Tracking

Manual tracking relies on spreadsheets, logbooks, or shared documents to record maintenance activity. The primary use case is very small fleets with low vehicle usage.

- Relies on paper files or spreadsheets

- Updates depend on individual follow-through

- Limited visibility across the fleet

- Higher risk of missed or duplicate records

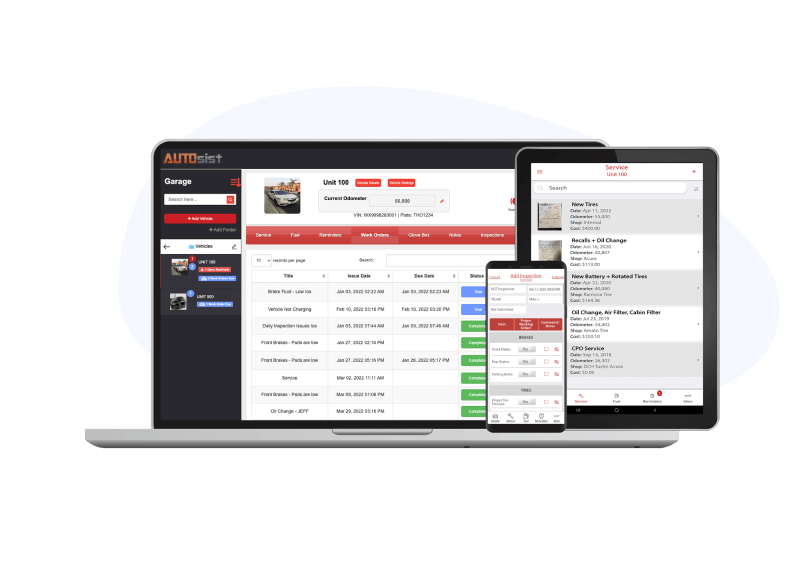

Digital Tracking

Software-based tracking centralizes maintenance data and automates routine tasks like reminders and reporting. The primary benefit is consistency as fleet size and complexity increase.

- Centralized maintenance records

- Automated reminders and schedules

- Consistent data across vehicles

- Easier reporting and auditing

Establish a Maintenance Tracking Framework

A maintenance tracking framework defines what is tracked, how it is tracked, and who is responsible for keeping records accurate. Without a defined framework, maintenance data becomes inconsistent and difficult to use operationally.

- Define which vehicles, equipment, and trailers are included

- Assign responsibility for data entry and review

- Standardize service categories and terminology

- Align maintenance intervals with OEM and regulatory guidance

Outcome:

- Clear ownership of maintenance records

- Consistent tracking across the fleet

Capture And Centralize Maintenance Data

Effective tracking depends on capturing complete and consistent data from every maintenance activity. Centralization ensures information is accessible and usable across teams.

- Record date, mileage, service type, and parts used

- Attach supporting documents such as invoices or inspection notes

- Ensure odometer readings are captured at service time

- Store records in a single system rather than multiple files

Outcome:

- Reduced data gaps

- Improved record accuracy

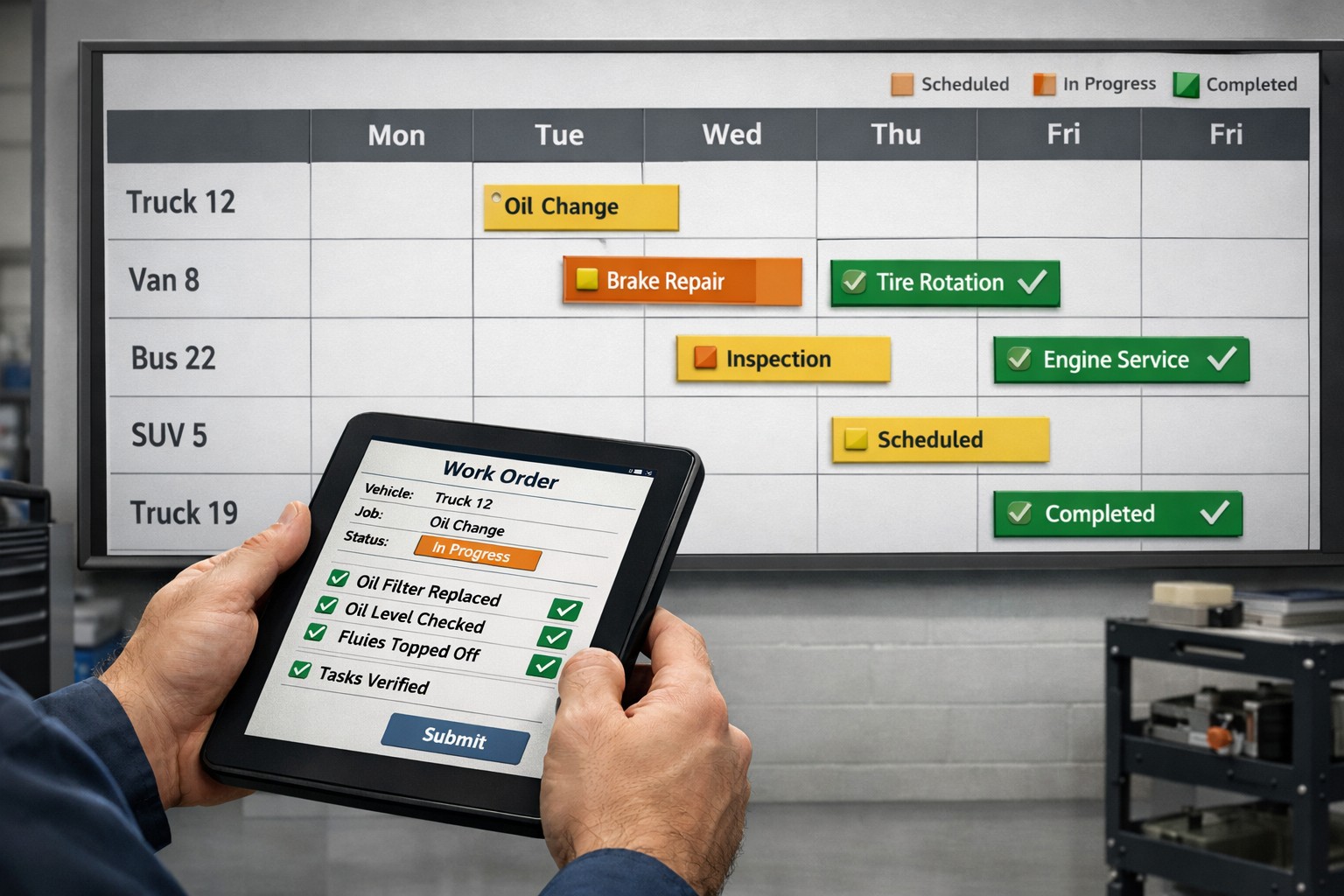

Schedule, Monitor, and Verify Maintenance Activities

Maintenance tracking is not limited to recording completed work; it also includes monitoring upcoming service and verifying completion against plan.

- Create preventive schedules based on time, mileage, or engine hours

- Track overdue and upcoming services by vehicle

- Verify work completion against scheduled tasks

- Flag repeated issues or deferred maintenance

Outcome:

- Fewer missed services

- Better maintenance compliance

Review Performance and Improve Maintenance Decisions

Tracked maintenance data should be reviewed regularly to identify trends, risks, and opportunities for improvement. This review step closes the maintenance loop.

- Analyze service frequency and recurring repairs

- Review maintenance cost trends by vehicle or asset type

- Monitor downtime related to maintenance events

- Adjust service intervals based on real-world usage

Outcome:

- Data-driven maintenance decisions

- Improved fleet reliability

Final Takeaways

A structured approach to tracking fleet maintenance creates reliable records, supports preventive planning, and improves long-term fleet performance. When tracking is consistent and centralized, maintenance data becomes an operational tool rather than a compliance burden.

- Define a clear tracking framework before collecting data

- Centralize records to improve visibility and consistency

- Monitor scheduled maintenance, not just completed work

- Use maintenance data to guide future decisions

AUTOsist Fleet Management Resources

What Is Fleet Maintenance Software

Fleet Maintenance vs. Fleet Management Guide

Why Preventive Maintenance Checklists and Schedules Are Essential for Fleet Operations

Fleet maintenance software that’s easy to use and improves fleet operations