Preventive Maintenance Schedule Template

A preventive maintenance schedule template is a structured document used to plan, record, and control recurring vehicle and equipment service activities. In fleet operations, it supports consistency, compliance readiness, cost predictability, and asset lifespan management.

Maintenance Interval Planning Matrix

| Asset Type | Mileage/Hour Interval | Time Interval | Service Category |

|---|---|---|---|

| Light-Duty Vehicles | 5,000 miles | 6 months | Oil & Inspection |

| Heavy Trucks | 15,000 miles | 3 months | Full Service |

| Construction Equipment | 250 hours | 2 months | Fluid & Filter |

| Trailers | 10,000 miles | 12 months | Brake & Tire |

| Service Vans | 7,500 miles | 6 months | Preventive Check |

Mileage-Based Scheduling vs Time-Based Scheduling

Mileage-Based Scheduling

- Aligns maintenance with actual vehicle usage

- Suitable for high-utilization fleets

- Reduces risk of overdue mechanical wear

- Requires accurate odometer or telematics data

Time-Based Scheduling

- Ensures periodic inspections regardless of mileage

- Useful for low-utilization or standby vehicles

- Supports compliance and warranty requirements

- Simpler to administer when mileage tracking is inconsistent

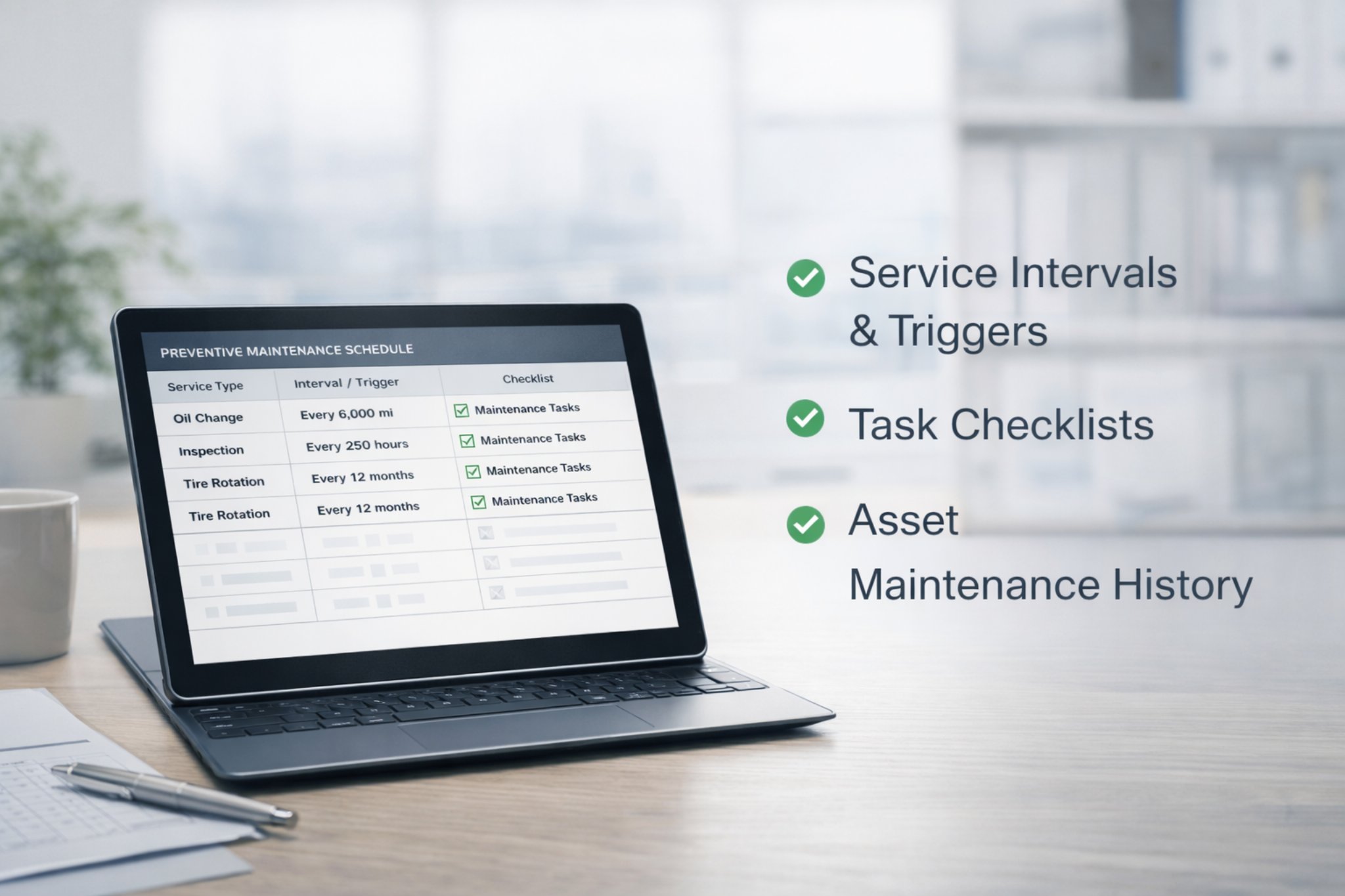

What a Preventive Maintenance Schedule Template Includes

A template standardizes the minimum data needed to plan and verify recurring maintenance tasks across vehicles, equipment, and trailers. Consistent fields reduce omissions and support audit traceability.

- Asset identifier (vehicle number, VIN, or equipment ID)

- Service type and scope (inspection, fluid change, component check)

- Interval logic (mileage, engine hours, or calendar date)

- Last service date and next due threshold

- Assigned technician or vendor responsibility

Operational Outcome

- Clear maintenance visibility

- Reduced record fragmentation

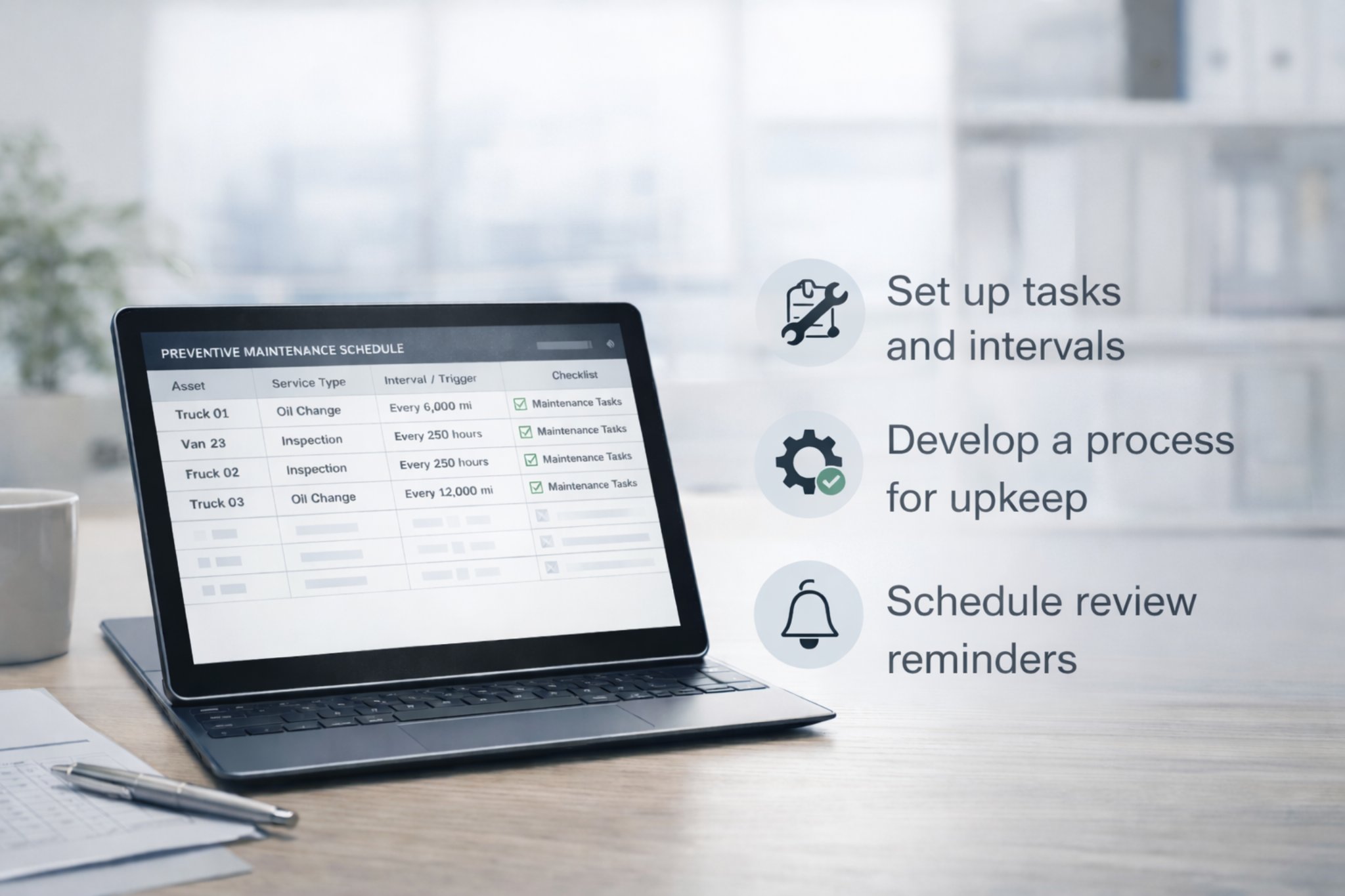

How to Build and Maintain a Preventive Maintenance Schedule

Creating a schedule requires aligning manufacturer guidance, regulatory expectations, and real-world usage patterns. The template becomes the control point for execution and updates.

- Start with OEM or regulatory baseline intervals

- Adjust intervals based on duty cycle and environment

- Define service categories (minor, major, seasonal)

- Assign ownership for updates and approvals

- Review schedules quarterly using performance data

Operational Outcome

- Predictable service cadence

- Improved planning accuracy

Operational Benefits of Using a Standardized Template

Standardization improves coordination between maintenance teams, drivers, and management. It also strengthens documentation quality and reporting consistency.

- Fewer missed or duplicate service events

- Improved budget forecasting for parts and labor

- Easier compliance documentation during audits

- Better cross-team communication on asset status

- Structured data for performance metrics and KPIs

Operational Outcome

- Lower unplanned downtime

- More reliable maintenance history

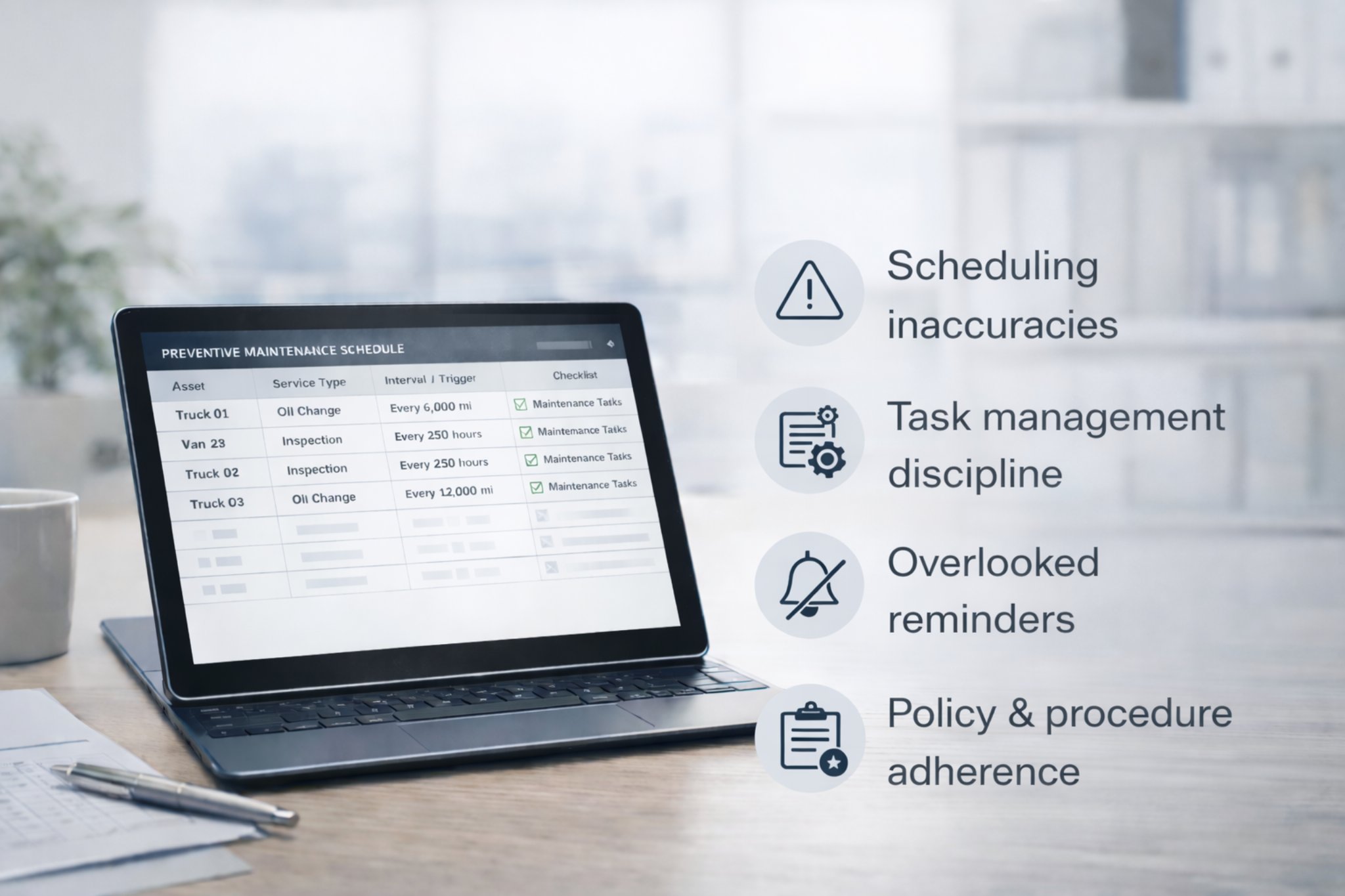

Common Implementation Challenges and Controls

Templates can fail if data discipline or ownership is unclear. Controls ensure the schedule remains accurate and actionable rather than static.

- Incomplete or delayed data entry → enforce daily or weekly updates

- Interval drift due to changing usage → schedule periodic recalibration

- Limited visibility across teams → centralize records

- Manual reminder gaps → use automated alerts where possible

- Version inconsistencies → maintain a single approved template source

Operational Outcome

- Higher data integrity

- Consistent execution across locations

Final Takeaways

A preventive maintenance schedule template functions as an operational control document that links planning, execution, and verification. When consistently maintained, it supports cost control, safety, and asset longevity.

- Use both mileage and time logic where appropriate.

- Align intervals with OEM guidance and real-world duty cycles.

- Standardize data fields to reduce omissions and duplication.

- Review and recalibrate schedules using performance data.

- Maintain a single source of truth for all maintenance records.

AUTOsist Fleet Management Resources

Fleet Manager Guide

How to Track Fleet Maintenance

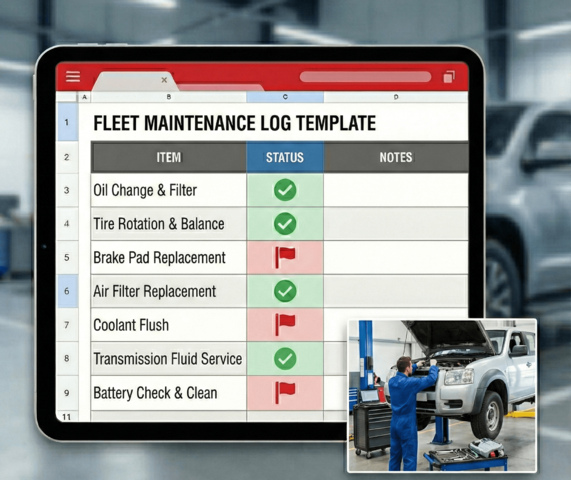

Fleet Maintenance Log Excel Template

Fleet Preventive Maintenance Schedules