When Fleet Maintenance Software Fails (And Why)

Fleet maintenance software failure does not usually mean the system stops working; it typically means the fleet stops using it correctly or consistently. When adoption, configuration, or data discipline breaks down, operational visibility declines, compliance exposure increases, and maintenance decisions revert to guesswork.

Failure Symptoms and What They Indicate

| Symptom | Likely Cause | Affected Area | Immediate Action |

|---|---|---|---|

| Missing service history | Incomplete data entry | Compliance & audits | Standardize record logging |

| Unused inspection module | Training gap | Safety & defect tracking | Re-train drivers and techs |

| Repeated emergency repairs | Reactive scheduling | Downtime & costs | Activate preventive schedules |

| Inaccurate mileage data | Manual entry errors | PM timing accuracy | Enable automated odometer sync |

| No performance reports | Reporting not configured | Decision-making | Configure dashboards |

Partial Implementation vs. Full Implementation

Partial Implementation

- Limited modules activated

- Inconsistent data capture

- Manual spreadsheets still used

- Reduced audit readiness

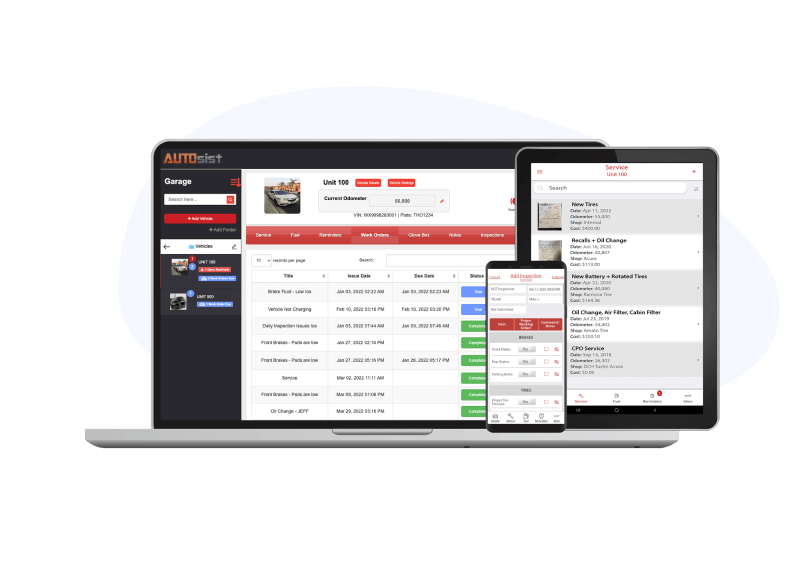

Full Implementation

- All core modules configured

- Centralized, real-time records

- Automated reminders and alerts

- Higher data reliability and traceability

Common Failure Scenarios in Fleet Maintenance Software

Fleet systems often fail operationally when visible functionality exists but daily workflows do not depend on it. The system becomes a reference archive instead of an active control tool.

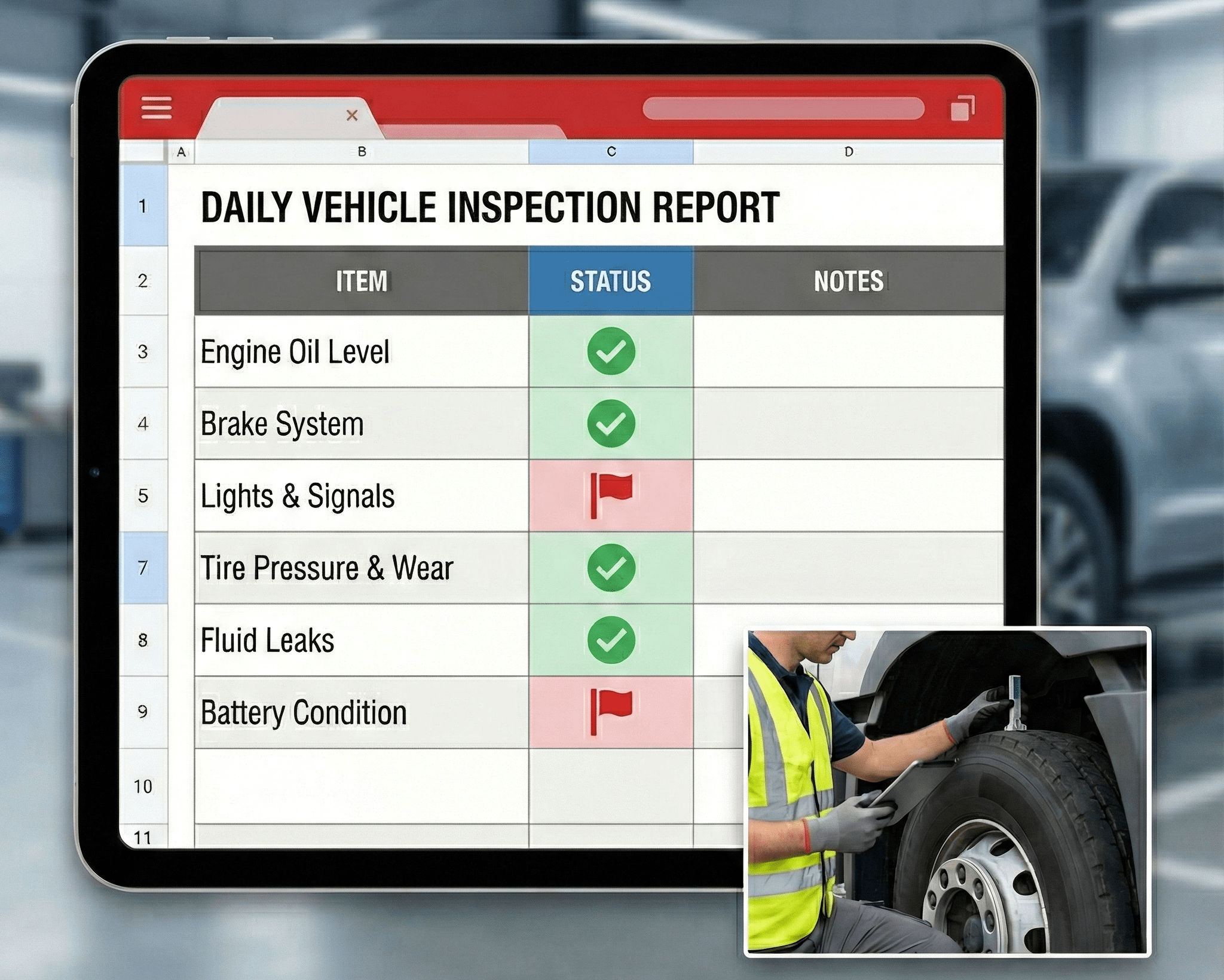

- Inspections completed on paper but not entered digitally

- Work orders created inconsistently or after repairs occur

- Preventive schedules configured but never reviewed

- Parts inventory not updated after usage

- Reports generated only during audits

Outcome indicators

- Increasing unplanned downtime

- Declining data accuracy

Root Causes Behind Software Failure

Most failures originate from organizational practices rather than technical limitations. Without defined ownership and procedural alignment, even feature-rich systems degrade into passive storage tools.

- No assigned system administrator or fleet data owner

- Insufficient onboarding or refresher training

- Expectations focused on software instead of process change

- Legacy habits such as spreadsheet duplication

- Lack of executive enforcement or review cadence

Outcome indicators

- Duplicate data sources

- Low user accountability

Operational Risks When Software Fails

When the system is not trusted or not used consistently, operational decisions lose evidence support. This increases exposure across compliance, cost control, and safety domains.

- Audit documentation gaps and delayed retrieval

- Higher frequency of roadside breakdowns

- Inaccurate maintenance forecasting

- Escalating repair costs from missed PM cycles

- Reduced visibility into vehicle utilization

Outcome indicators

- Reactive maintenance patterns

- Increased inspection failures

Prevention and Recovery Strategies

Stabilizing a failing system requires procedural correction rather than immediate replacement. Structured review and re-alignment typically restore effectiveness.

- Assign a single accountable fleet system owner

- Conduct quarterly configuration and data audits

- Mandate digital inspection completion for all drivers

- Integrate work orders, parts, and service history into one workflow

- Establish reporting review meetings with operations leadership

Outcome indicators

- Improved data completeness

- Predictable maintenance cycles

Final Takeaways

Fleet maintenance software fails when usage discipline, configuration accuracy, and data ownership decline—not merely when technology is inadequate.

- Treat the system as an operational control tool, not a record archive.

- Assign clear responsibility for configuration and data accuracy.

- Eliminate duplicate tools that fragment maintenance history.

- Review preventive schedules and reports on a fixed cadence.

- Align training and enforcement with daily workflows.

AUTOsist Fleet Management Resources

How to Track Fleet Maintenance (Step-by-Step)

Fleet Compliance Guide

Daily DVIR Vehicle Inspection Checklist PDF

Fleet Maintenance Software