Miya Bholat

Miya Bholat

July 13, 2021

6 Fleet Truck Maintenance Tips to Improve Efficiency and Costs

Keeping your drivers and your fleet trucks safe and productive on the road is the best way to achieve success in your business and it all starts with having a well-maintained and reliable fleet. Fleet maintenance and parts expenses can get rather expensive and difficult to manage if you do not have a system to help you.

Have you ever heard of preventative maintenance? Well, this maintenance approach is necessary for fleets to get in front of issues and repairs before they arise. When it comes to fleet truck maintenance especially, prevention is key, and taking care of your trucks routinely can prevent a massive expense down the line. Having to replace a diesel engine because you missed routine maintenance will also put the vehicle out of commission for a length of time, which can impact productivity and rental or replacement costs you did not plan for.

It is also worth mentioning that well-maintained trucks are more fuel efficient, go through way fewer tires, and experience breakdowns far less than those who don’t get regular maintenance. Consider these six tips for fleet truck maintenance to keep those trucks rolling.

6 Tips for Fleet Truck Maintenance

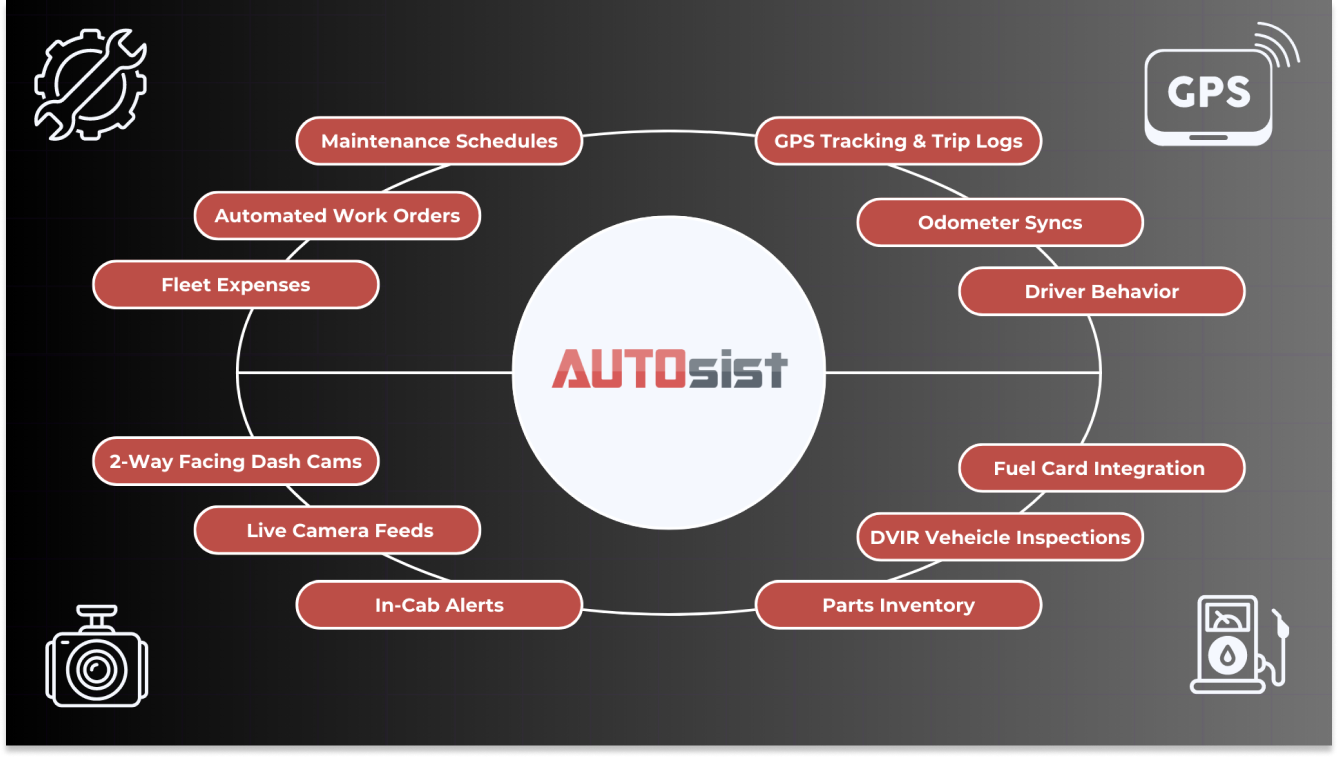

1. Turn to fleet maintenance software

One of the best things you can do for your fleet is investing in an easy-to-use, reliable truck maintenance software. Investing in truck maintenance software is going to make daily tasks much easier, and it’s going to make the data of your business much more accurate and up to date.

In the past, the only way to know if a vehicle was due for maintenance was to maintain a calendar for each vehicle and use paper inspection forms where drivers could confirm if there was an issue or repair needed that day. Yes, this system might work if you have two or three vehicles, but if you have 10 or more trucks in your fleet, the risks of your team forgetting or an error to occur are magnified.

Having your employees fill out long, handwritten paperwork daily is a tall order and often gets overlooked. But, investing in a truck maintenance software like AUTOsist, gives your team a system to input their data and a place for you to have automated maintenance schedules and repair reminders that create work orders for you to give to your maintenance staff. Going digital means you have a flow of communication and immediate updates from identifying a repair to the length of time and parts used to complete the service.

2. Create custom vehicle inspections

Another thing you should be doing regularly to maintain your fleet of trucks is regular inspections. Whether you are a commercial vehicle that requires daily inspections to be compliant or not, this is something you should incorporate into your routine to ensure the longevity of your fleet of vehicles.

Not only should you enforce drivers complete routine truck inspection prior to each trip, but you should also customize each inspection form for each type of truck or piece of equipment – after all, a class-8 truck does not have the same components as your medium-duty truck or trailer.

Using a mobile vehicle inspection app, you can simply create a unique set of inspection requirements for each type of truck or piece of equipment, so drivers can quickly and thoroughly submit inspections. Another great feature of an inspection app is that drivers can submit pictures of issues, which informs maintenance staff far greater than a brief summary could. Plus, it saves big on time to complete so your drivers can hit the road faster.

3. Cost savings analysis and your budget

Yes, we must address the dreaded budgeting talks everyone hates discussing. Preparing a budget and doing cost savings analysis is one of the most important aspects of fleet maintenance management. If you don’t review your maintenance work orders, parts inventory, and amount spent, you have no idea how much your fleet could be weighing down the business.

Let say you have a fleet of 12 class-8, six of brand A and six of brand B trucks. After some research and comparing your two brands of trucks, you found B to be the most reliable truck in terms of having less breakdowns and cost to repair. This information leads you to then purchase or lease all of brand B trucks when the time comes to replace your aging fleet.

In another scenario, imagine not track of which tire brand was used in a work order and then comparing it against two other brands you used on similar trucks. You might find that one brand lasts longer than the others, which allows you to buy in bulk and save on replacing all your truck’s tires.

4. Create a line of communication amongst your fleet

Depending on the size of your fleet, you may have multiple different drivers using the same truck. One of your trucks may have had some sort of engine issue one day, but it may have not been recorded because they forgot to fill out the paperwork and they didn’t communicate it to anyone in the company.

Then, your next driver comes in and takes that same truck for the day and blows the engine! The driver wasn’t sure why it happened, then come to find out it was having issues before and no one reported it. The key to truck maintenance is communication between drivers and fleet managers so you can avoid instances like this. With AUTOsist, we make communication between team members easy and convenient, so you are always informed.

5. Create fleet reports

Another thing many dread but is absolutely necessary is reporting. No matter what you have going on, keeping and updating reports for your fleet is extremely important to keep a pulse on the health of your trucks. Some of the necessary fleet reports re fuel costs, parts expenses for repair work orders, and daily reports from your vehicle inspections, which you will want to have a historic log of in case of an inspection blitz or audit.

These are all very important things that you and your team need to stay on top of to properly maintain your vehicles, AUTOsist allows you to upload, update, and download all your daily, weekly, or monthly fleet reports all in one place.

6. Plan ahead

When it comes to proper fleet truck maintenance, you want to ensure you have proper truck maintenance solutions in place before you add on any vehicles or drivers. You want to avoid a situation where you have to hire five or six new drivers, purchase new trucks and have no system in place for them to follow. Having a system and routine in place before an expansion is much easier to manage than trying to enforce it after the fact. Plus, having a system to maintain vehicles will make certain you address issues immediately and your trucks will last longer and be safer to operate.

To learn more about AUTOsist and learn how it can help you manage your truck fleet request a demo today!